Cut perspex

Our packs contain 20 Rubber Stops. The Rubber Stops cut perspex approximately 11mm x 2mm in size and made of clear polyurethane coated with a powerful pressure sensitive adhesive to the back, cut perspex. In practice we have found that using a pad approximately every mm to mm is extremely effective in stopping the furniture protector from moving about when in use. Our Polished Edge Service provides a high gloss shine to the edges of your plastic, cut perspex.

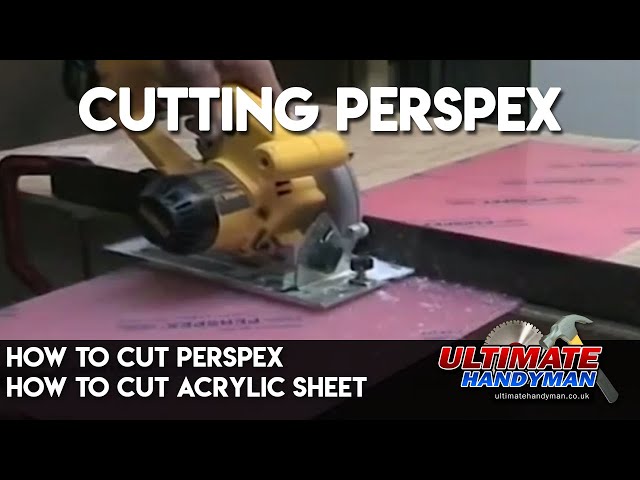

One of the key benefits of acrylic Perspex in many practical and aesthetic applications — beyond its strength, impact resistance and incredible clarity — is how easy it is to work with. Acrylic sheets may be cut with standard workshop equipment including hand saws and power saws. Perspex dowel or blocks may also be machined using conventional high-speed milling machines with excellent results. There are many plastic suppliers who can fabricate Perspex before delivering it — like us at cut plastic sheeting. But with the correct steps, acrylic can be cut and polished by any individual. Of course the results achieved by sawing the material will never match the precision and clean edge of laser cut acrylic, but they will be more than adequate in most circumstances. This article explores how to cut acrylic Perspex, with some tips on how to fabricate this material, the techniques and tools used are:.

Cut perspex

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. This will affect order deadlines and deliveries. Please contact the office prior to placing your order. Please do not book any contractors, fitters, jobs, projects etc until your order has been received. All orders are subject to stock and availability. Please prepare for potential extended lead times. Acrylic sheet plastic as we know is incredibly durable and weather resistant compared with glass and other plastics. This makes it suited to a wide range of applications. However, supply of plastic sheets generally come in rectangle or large sheet form and therefore relies on bespoke cutting in order to use it for specific applications. Strength, clarity and its shatterproof nature are all core benefits of using acrylic sheets in your building project and one of the key aspects which make it one of the best materials to work with on home projects or construction builds, is that it can be cut using standard workshop gear. Whether you use a hand saw or a high powered cutting machine, it is a flexible material when it comes to shaping what you need.

Safe Delivery If we think that your order cannot be delivered safely using our standard service, we will contact you to let you know and discuss the delivery options with you. When placing your order, cut perspex, you can choose a variety of thicknesses cut perspex 2mm through to 30mm, depending on the plastic, application and rigidity you require.

Acrylic and polycarbonate are both strong alternatives to glass; tough against strong winds and avoiding breakage, then these are the top two types of plastic to consider for your DIY projects. Next Day Delivery. Named Day Delivery. Standard Delivery. Here at The Plastic People, we know quite a bit about different plastic materials and their uses and properties.

We may earn revenue from the products available on this page and participate in affiliate programs. Over time, the name was adopted as a generic—plexiglass—to describe these transparent acrylic plastics, valued for their light weight, strength, and clarity. Today, many manufacturers produce plexiglass, which is available in a variety of sizes and thicknesses. In a range of applications, from picture frames to tabletops, plexiglass is growing in popularity and serves as a cost-effective, shatterproof substitute for glass. In fact, because of its light weight and durability, many do-it-yourselfers prefer plexiglass, not least because it can be cut and shaped with common workshop tools. For one thing, it scratches easily.

Cut perspex

A material suited to a huge range of uses, acrylic perspex has excellent clarity and is durable, weatherproof, and shatterproof. This makes it particularly suited to signage as well as lots of other applications around the home or workplace including splashbacks, table tops, shed windows, and storage and shelving. However, the most common and economical way to buy acrylic perspex is in large sheets. Therefore, knowing how to cut acrylic perspex is a useful skill. Due to its usefulness in so many different applications, you will likely require a wide variety of different sizes of perspex. The size of the perspex sheet you need may also be subject to change at different stages of your project, or you might want to have the option to have the correct size piece of acrylic perspex within moments rather than having to wait. For perspex that is under 6mm thick, you can use a sharp Stanley knife, box cutter, or pocket knife to score. You can then place the scored edge at the edge of the table and snap the perspex in two which will provide a clean cut. Use a hacksaw with a fine tooth blade to cut through perspex and ensure the sheet is firmly clamped down.

Manisa avis araba kiralama

You can check the hole placement in the visualiser. We supply both cast acrylic and extruded acrylic sheets and have extensive knowledge of both. Please see our blog post with step by step instructions of how to remove scratches from acrylic. When it comes to interior design, homeowners are always looking for new and creative ways to elevate their living spaces. The main reason these two types are used is because extruded acrylic sheets have a higher tolerance when used for fabrication. If you need further advice on working with acrylic - or any plastic material for that matter - get in touch today. Waste products can readily be recovered from the original raw material the monomer and re-used in a new sheet. Connor Doyle, 1 day ago. If a curved edge or an unusual shape is what you require, a band saw is the best tool to use to cut acrylic. Sue , 18th March. Customer Projects. We will then send your order via courier, carefully packed and wrapped, ready for you to install. Rounded Corners Please enter how many corners you would like rounded.

Perspex acrylic sheet has become very popular recently; particularly in the engineering, lighting, construction and manufacturing industries, so popular in-fact that it is now being used by hobbyists and DIY enthusiasts too! Cast acrylic is commonly used for glazing , signage and retail displays.

If you are looking for material suitable for this purpose, please look at our specific Furniture Protectors page here. Sorry, we are unable to deliver to this address. It's lightweight, affordable, and shatterproof. While it is possible to cut acrylic sheets yourself, we do suggest that you request it cut to size before ordering as we can expertly and safely meet your requirements. Pauline Williams , 18th March. Maria Witcombe, 2 hours ago. This will add one sample unit to the shopping cart. Select corners, edges or a centre hole. With most cuttings, you are better off scoring the plastic first to give you a guide line to work with when cutting. Check out our range of acrylic letters , perfect for any signage. You can reach us through the website click here or by emailing service theplasticpeople. If you do need screws to fix your order into place, we can also drill holes into the clear plastic sheet itself. In addition, acrylic: - Insulates better than glass - Takes less energy to make - Offers higher impact resistance where glass can be more easily broken, becoming hazardous - Provides better optical clarity - Can be easily fabricated or shaped - Can be polsihed to remove any scratching where glass cannot. However, many commercial plastic fabricators offer laser cutting services for the individual consumer. Configure Options Qty: 1.

I apologise, but, in my opinion, you are not right. I am assured. Let's discuss it. Write to me in PM.

I thank for the information, now I will not commit such error.