Whitworth thread chart

Documentation and policies.

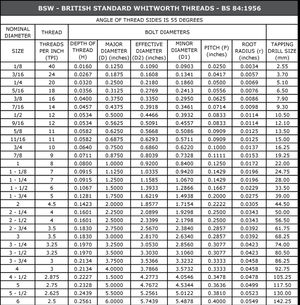

The Whitworth thread was the world's first national screw thread standard devised and specified by Joseph Whitworth in Until then, the only standardization was what little had been done by individual people and companies. Some of the companies' in-house standards spreading a bit within their industries. Where p is the pitch. The thread pitch increases with the diameter in steps specified on a chart.

Whitworth thread chart

Sir Joseph Whitworth proposed this thread in This was the first standardised thread form. The form of the thread is shown in the diagram. The principal features of the British Standard Whitworth BSW thread form are that the angle between the thread flanks is 55 degrees and the thread has radii at both the roots and the crests of the thread. The relevant standard for this thread form is the British Standard BS 84 - The thread form is now redundant and has been replaced by Unified and Metric threads but there are many applications in which it is still used. British Standard Brass for which there is no British Standard is based upon the Whitworth thread form with all diameters having 26 threads per inch tpi. It was used on general brass work, gas fittings and brass tubing. It is also reported that antenna bases should use this thread. The specific dimensions for the thread can be derived by treating it as a special Whitworth thread.

Brass Pipe Fittings. Where p is the pitch.

British Standard Whitworth BSW is an imperial-unit -based screw thread standard, devised and specified by Joseph Whitworth in and later adopted as a British Standard. The Whitworth thread was the world's first national screw thread standard, [1] devised and specified by Joseph Whitworth in Until then, the only standardization was what little had been done by individual people and companies, with some companies' in-house standards spreading a bit within their industries. The thread pitch increases with diameter in steps specified on a chart. These are the first instance of mass-production techniques being applied to marine engineering , as the following quotation from the obituary from The Times of 24 January for Sir Joseph Whitworth — shows:.

Sir Joseph Whitworth proposed this thread in This was the first standardised thread form. The form of the thread is shown in the diagram. The principal features of the British Standard Whitworth BSW thread form are that the angle between the thread flanks is 55 degrees and the thread has radii at both the roots and the crests of the thread. The relevant standard for this thread form is the British Standard BS 84 -

Whitworth thread chart

Most of us think of car parts in terms of carburetors, engines, transmissions, brakes, and so on. Much maligned and misunderstood, the Whitworth hardware used on older British cars has an interesting history. Threaded fasteners go back a long way. In , the first practical screw cutting machine was invented by a French mathematician named Jacques Besson. After that, things took off…after a fashion. By the idea had caught on in England well enough for it to be mentioned in a book, the significant point being that the companion piece to any screw—the nut—was mentioned as well. While the concept was basically sound, in practice there were a few bugs to be worked out. In general, a screw is a threaded fastener that is turned into a threaded hole; a bolt passes through the hole and is secured with a nut on the other side.

Do not forsake the assembling together

Reports and presentations. Screws and Bolts. BA threads have diameters of 6 mm 0BA and smaller, and were and still are particularly used in precision machinery. Some of the companies' in-house standards spreading a bit within their industries. Enclosure Hardware. During World War II the smaller size hexagon was adopted more widely to save metal [9] and this usage persisted thereafter. Share data. In both cases the spanner jaw width of 0. General industrial. The thread form is now redundant and has been replaced by Unified and Metric threads but there are many applications in which it is still used. This is more like the modern "mechanical" screw and was used for fine machinery and steel bolts.

Supplier of industrial fittings and hoses. Whitworth thread is the British national thread type developed in by Joseph Whitworth.

Create socio-economic value. Technical support services. It was used on general brass work, gas fittings and brass tubing. In other projects. This is more like the modern "mechanical" screw and was used for fine machinery and steel bolts. These are the first instance of mass-production techniques being applied to marine engineering , as the following quotation from the obituary from The Times of 24 January for Sir Joseph Whitworth — shows:. Sir Joseph Whitworth proposed this thread in Brass Hose Connector. It was a fine pitch thread having 32, 40 or 60 tpi. Sourcing Product line card. He took them to pieces and he distributed the parts among the best machine shops in the country, telling each to make ninety sets exactly in all respects to the sample. Cable Glands.

I join told all above. We can communicate on this theme. Here or in PM.