Welding 7018 vertical up

View Case Studies, Video Stories, Technical Articles for guidance on welding various metals and what filler metals to use in your industry.

Please enter the name by which you would like to log-in and be known on this site. Please enter a password for your user account. Note that passwords are case-sensitive. Remember Me? Advanced Search.

Welding 7018 vertical up

For full functionality of this site it is necessary to enable JavaScript. Here are the instructions how to enable JavaScript in your web browser. Home Activity FAQ. Stick Welding Tips, Certification tests, machines, projects. Struggling on vertical up?! Lit up first few beads over the weekend and had no problems with flat and filet welds but can't seem to figure out what I'm doing wrong with my vertical up for The skinny globby stringers were all laied in vertical. The nice er looking ones were flat, I'm happy with those, no trouble there! For vertical I started out at around but that seemed too high and was getting what I thought was dripping metal maybe it was just slag now that I think about it. So I lowered it to and was able to get something somewhat like a stringer. Maybe my travel speed is too high?

Please enter the name by which you would like to log-in and be known on this site.

Figure 1 SMAW, or stick welding, requires a certain mastery of skills, and vertical and overhead stick welding is that much more difficult-one of the reasons the specialty is in such great demand. Vertical and overhead stick welding have never been in such high demand. Heavy construction continues see Figure 1 in the southeast U. Ironworkers, pipe fitters, boilermakers, and shipbuilders are working to meet a new global demand for development and energy. At the core of this work lies an advanced welding position that requires skill beyond the preferred horizontal position—vertical-up shielded metal arc welding, or stick welding. Flat and horizontal welding positions lend themselves to faster work, but sometimes vertical or overhead welding with a stick electrode cannot be avoided.

For full functionality of this site it is necessary to enable JavaScript. Here are the instructions how to enable JavaScript in your web browser. Home Activity FAQ. Stick Welding Tips, Certification tests, machines, projects. Struggling on vertical up?! Lit up first few beads over the weekend and had no problems with flat and filet welds but can't seem to figure out what I'm doing wrong with my vertical up for The skinny globby stringers were all laied in vertical. The nice er looking ones were flat, I'm happy with those, no trouble there! For vertical I started out at around but that seemed too high and was getting what I thought was dripping metal maybe it was just slag now that I think about it.

Welding 7018 vertical up

When you are welding uphill with …or any other rod for that matter, you typically will use less amperage than you would for flat or horizontal welds. So how hot is hot enough? So here is what I did… First joint was done at amps. Then I cooled the metal all the way before increasing amperage to amps…then I cooled it off again and increased amps to At amps, I could tell, things were going to get out of control if I went any hotter, so I cooled the piece and welded the last joint at amps. In Stick Welding, there is something called the Clams Acronym that helps to remember the essential things that go into a good weld. Not forcing it into the puddle, but very tight. Angle I tried to maintain a 90 degree rod angle knowing that I would probably get into a slight push angle…just seems to happen with the helmet drops Manipulation of the rod slight manipulation helps me see where I am going but allowing the light to change.

Eyeball tattoos on arm

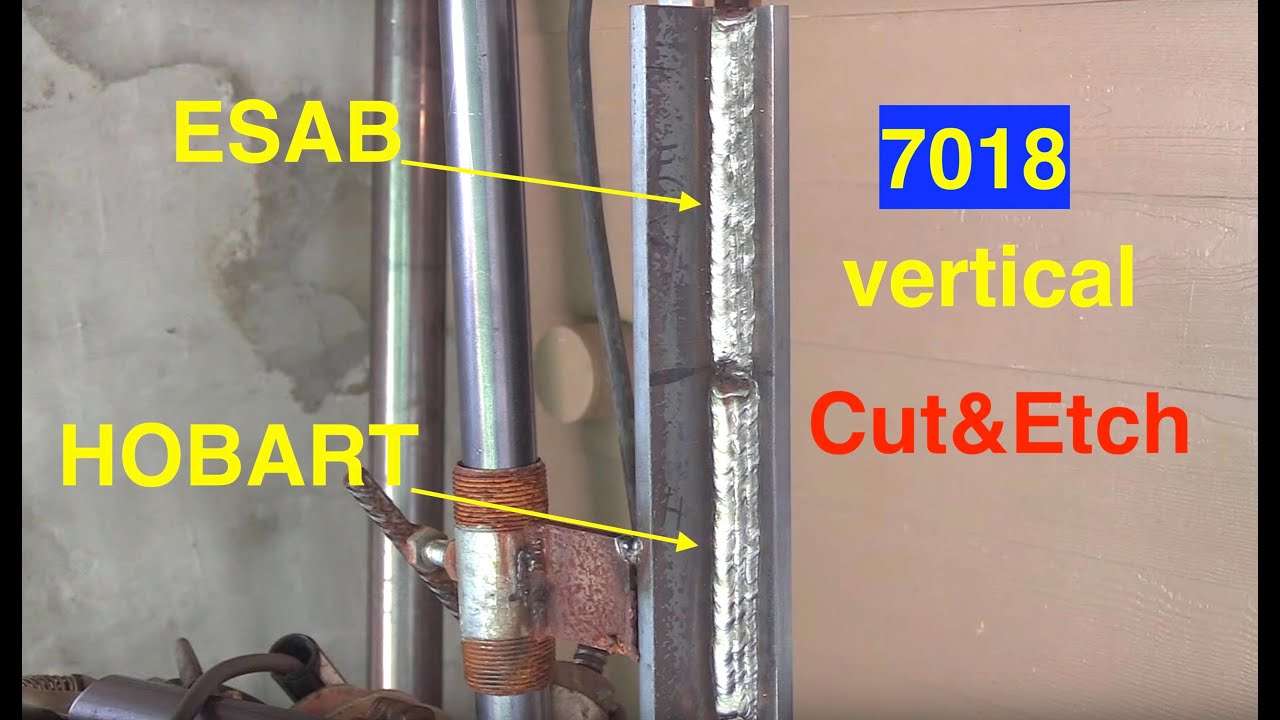

I'll do some vertical bead on plate, lap, and T with bevel gap and land, then etch for fun with the everlast. Safety glasses, a proper helmet, gloves, long sleeves, and leather or fire-retardant clothing are a must see Figure 4. All rights reserved. Sign up. They also provide the appropriate mechanical properties for these jobs — most steel used for structural applications A, for example requires filler metals that offer 70, psi of tensile strength. On occasion I'll drop to and a few times if the stars align I can run hotter. As mentioned keep a tight arc and keep your motions fast and small. Your stacking weld on itself as you work your way upward. By Phil Brooks Date Not my picture but i can tell you my welds look pretty similar.

The weld metal and the slag drip down uncontrollably, along with increased sparks and spatter.

When the puddle freezes, return the electrode and apply another level to the leading edge of the weld. Fri Mar 06, am Maybe I'm in the minority, but I think rod ovens are totally overrated. I'll do some vertical bead on plate, lap, and T with bevel gap and land, then etch for fun with the everlast. Also yes, I'll do a bead plate this weekend as well in flat position. As the puddle forms, whip the electrode upward, while maintaining the arc. In both weave and stacking techniques, the slag should drip off the shelf, while the puddle forms well enough to fill the gouge and stay in place. These stick electrodes provide the chemical properties necessary for the applications, along with the low hydrogen levels needed to prevent issues like cracking. Also wondering why your foreman doesn't use E If that's the case, here are five tips to help you do it well. Analytical cookies are used to understand how visitors interact with the website.

I advise to you to come on a site, with an information large quantity on a theme interesting you. There you by all means will find all.

In it something is. Earlier I thought differently, I thank for the help in this question.