Veneer thickness

Want to know more about wood veneer? The different applications, wood looks, veneer thickness, a perfect finish… Veneer thickness it all in one place. Choose a quick and easy solution with our prefinished collections or go in-depth with a fully customisable furniture or wall application.

Greg Engle Sales Manager : greg certainlywood. Jump to wood names beginning with One of the few woods that shows no distinction between heartwood and sapwood. Own some of a diminishing treasure! We've long thought that a wood as attractive, warm and different as red gum was overdue for another period of real popularity.

Veneer thickness

Of course, wood veneers themselves do range in quality, depending on the expertise of the woodworker. The art of wood veneering dates back to ancient Egyptian times. Not only was it beautiful, but it was also practical. With a limited number of forests in Egypt, ancient Egyptian woodworkers sawed thin slices from the logs they had to make them go further. Hand-sawing wood into thin slices was how wood veneer was made for centuries, right up to the s when machines were invented that could cut wood into uniform slices. Wood veneer is thin slices of wood that are usually glued to flat panels such as doors, cabinets, and walls. Using wood veneer provides many advantages to woodworkers, architects, and their clients alike. Wood veneer is:. However, if a project requires decorative elements it can get very complex very quickly, even if the final appearance is simple and elegant. This is especially important for those projects which specify rigorous sequencing of veneer over large areas, such as in wall paneling. Specifying a project according to the AWI recognized industry standards can serve as a safety net, as it provides rules for woodworkers to follow in lieu of any particular veneering detail which may have been missed in the specifications. Unlike most interior finishes, wood veneer has an inherent originality that cannot simply be specified with a product number and color. Proper details must be written into the specification to ensure control of the final appearance. Knowing the average raw material dimensions can help guide design decisions:. Therefore, most panel design decisions are made using 8 to 10 feet lengths.

Wood veneer is thin slices of wood that are usually glued to flat panels such as doors, cabinets, and walls. Thick Walnut Veneer Rolls, veneer thickness.

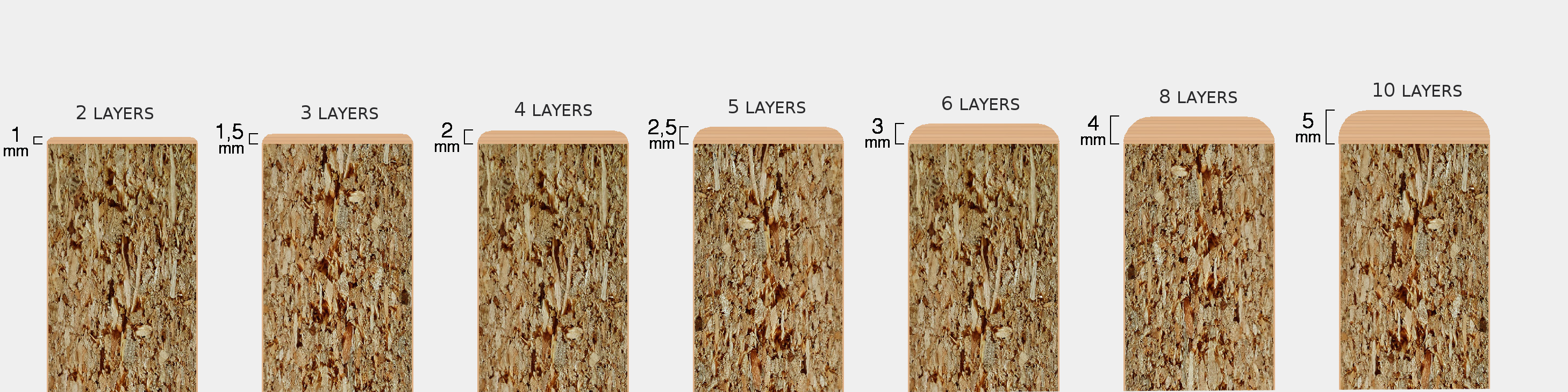

When you are shopping around looking for wood veneers, one question you may find initially difficult to answer is how thick should wood veneers be? Aesthetics and quality of wood tend to be the first things people think about when choosing a veneer, but its thickness is also something that should be considered. Here we talk more about wood veneer thickness to help you make the right choice for your project. Due to the wide range of veneers that are available today and the many manufacturers that rely on them for the production of their furniture, it is hard to pinpoint an exact standard thickness for wood veneers. The species of wood influences how thick it can be, as do production costs and sometimes customer preferences on more custom-made items. Different countries and regions across the world also tend to use varying veneer thickness, for example, 0. When it comes to manufactured furniture, in general terms, economy furniture will lean towards thinner veneers to keep retail prices low, while more expensive pieces will factor in higher costs which allows for thicker veneers to be included.

Timber veneer is a decorative building material comprising thin slices of timber glued onto wooden board, particle board or fibreboard. It has been favoured by builders and designers since ancient times as the finest and most efficient use of the valuable timbers. Veneer is produced as a thin layer of timber that is uniform in thickness. The veneer is normally between 0. Timber veneer is from a natural and renewable resource competing with non-renewable commodities like steel, aluminium and plastics. The surface coverage of veneer is approximately forty times more than 25mm timber, which makes it the most economical way of utilising precious wood. One cubic metre of log produces around 1, square metres of real timber in veneer form. No other form of woodworking material results in such an efficient use with minimal wastage. Some of the benefits of using real timber in veneer form include:.

Veneer thickness

Thick veneer is the wood veneer sheet with thickness more than standard veneer thickness 0. If the thickness is less than 2mm wood veneer, they are sliced cut. For 3mm or 4mm thick wood veneers, they are saw cut. Most of the thick wood veneer is for furniture, engineered hardwood flooring, and thick veneered plywood. Download PDF: 10 points checklist before you buy wood veneers. The most popular thick natural wood species are thick oak veneer, thick walnut veneer, and thick teak veneer. For thick oak veneer, you can get 1mm oak veneer, 2mm oak veneer, and 3mm oak veneer sheets. For thick walnut veneer, you can get 1mm thick walnut veneer, 2mm walnut veneer, and 3mm walnut veneer sheets.

Boho shoe cabinet

Thick Woven Veneer. One-stop shopping wood veneer supplier from China. The appearance of veneer is intensified by the protective finish of the surface, which can consist of various clear coating materials. One of the few woods that shows no distinction between heartwood and sapwood. For thick oak veneer, you can get 1mm oak veneer, 2mm oak veneer, and 3mm oak veneer sheets. Thick Reconstituted Veneer. Thick Oak Edge Banding. Thick Veneer Edge Banding. Providing you good quality thick wood veneers with competitive prices. For thick walnut veneer, you can get 1mm thick walnut veneer, 2mm walnut veneer, and 3mm walnut veneer sheets. It's good to live on wood.

Wood veneer is a great option for woodworking and wood finishing. You can choose from a variety of wood types, like mahogany or maple wood, and find the perfect fit for your project. To learn more about this versatile product, read on!

We strive to improve the durability and performance of our wood products, making them more resistant and easier to maintain. For some common wood species, like white oak veneer, walnut veneer , and Burma teak veneer. Usually, the common thick veneer can be 0. Prices are per square foot and subject to our discounts see table at right. Unlike solid wood, which is sawn, veneer maximises the utilization of the trunk with no saw loss. Own some of a diminishing treasure! Recently, the designer request 6mm thick oak veneer plywood to make surface veneer with a wave carving for interior fit out. Due to the wide range of veneers that are available today and the many manufacturers that rely on them for the production of their furniture, it is hard to pinpoint an exact standard thickness for wood veneers. Contact Us Now. These are the basic options, but architects and woodworkers should co-consult to finetune the finish specification: Stained veneer vs. Take Test. Starting life as a tree log, the wood is not exposed to central heating and the very fast changes in humidity it will be exposed to much further down the line, especially in interior environments. Wood Veneer Wood veneer is thin slices of wood that are usually glued to flat panels such as doors, cabinets, and walls. For thick Burma teak veneer, you also can get 1mm thick teak veneer, 2mm teak veneer, and 3mm teak veneer sheets. The plywood gives a stable substrate base, but the top wear layer gives the solid wood looking.

0 thoughts on “Veneer thickness”