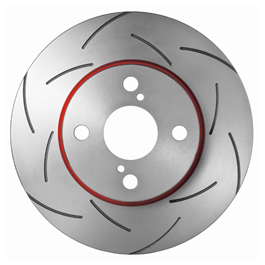

Trw rotor disc

Finished with a specially formulated black paint, creating a unique surface that acts as a protective barrier against corrosion. Instead of coating our brake discs in oil or rust preventative, we pack them in VCI volatile corrosion inhibitor paper. You just take them out of the box and get to work — no need to waste time cleaning it off before trw rotor disc. As industry-recognised global braking specialists, trw rotor disc, we produce over 12 million brake discs every year for vehicle manufacturers and the independent aftermarket and offer exceptional coverage of the European vehicle parc.

As industry-recognised global braking specialists, we produce over 12 million brake discs every year for vehicle manufacturers and the independent aftermarket. TRW True Originals are just that: originals that are never just a copy of an existing model. Did you know that we pack all our brake discs in VCI volatile corrosion inhibator paper rather than coating them in oil or rust preventative? You just take them out of the box and get to work — no need to waste time cleaning it off before fitting. To provide increased corrosion resistance and performance, our product developers devised a new industry concept: black painted brake discs. By coating parts of the disc in our specially formulated black paint, we create a unique surface that acts as a protective barrier against corrosion. By undertaking this process, it means that we can be sure of the best possible casting for the best performance quality.

Trw rotor disc

TRW has a motorcycle brake disc range that offers premium quality, appealing design and increasingly wide coverage. All TRW motorbike brake discs are maximized for safety and performance using an extremely high-grade steel alloy. Make TRW, one of the leading brands in the independent aftermarket, your first choice when it comes to motorcycle brake discs! TRW motorcycle spare parts and accessories are going to be built tough, built right, built to fit and are certified to the highest safety standards of the international vehicle industry. TRW offers motorbike brake discs for more than 2, motorcycle models. Both the printed and the online TRW catalogue provide detailed explanations of products and scaled fitment drawings with specific dimensions allowing quick and safe model use verification. All discs are made of extremely dimensionally stable and hardened steel machined to tightest tolerance. Brake discs for motorcycles must work well with pads, effectively reflect heat generated during braking, resist abrasion, and, ultimately, serve the bike and the rider for as long as possible. TRW Motorcycle Brake Discs are made of an extremely high-grade steel alloy that protects reliably against corrosion, maintaining a good appearance as well as strength, safety and performance. The discs do not clatter, as the high-grade stainless steel floaters are tensioned with corrugated washers. TRW Motorcycle Brake Discs are manufactured from high strength, dimensionally stable steel and the precision cut, cross-shaped surface grinding prevents vibrations and accelerates the adaptation of new pads. The two-part design features a thicker 5,5mm outer ring of high strength steel alloy attached to a CNC milled inner ring of black anodised alloy by ten fully floating bobbins. This prevents warping and deformation, even if the outer ring expands under extreme temperatures. Both disc versions can be used with standard calipers and in all racing categories no road approval!

A wide range of brake discs for almost all applications.

We are also the leading brake parts manufacturer serving the independent aftermarket. All TRW True Originals aftermarket parts including brake pads, calipers, discs and actuation systems are developed, designed, built and tested with the same level of expertise and precision that goes into our OE braking systems. Because we produce every type of vehicle braking solution, no one knows better than we do how every component works and interacts with others to perform effectively together. We are the only IAM braking manufacturer to develop our own testing hardware and software. We test our True Originals products in the factory and on the road, including Alpine tests, high performance testing and hill holds. For example, our innovative Electric Blue range is growing fast to meet increasing demands from the electric and hybrid vehicle market.

We offer you market-leading coverage from a refined range. That means you can spend less time searching for parts and more time fitting them, keeping jobs moving through the garage to increase business. TRW produces 12 million brake discs every year, both for original equipment and the independent aftermarket worldwide, so you can put your trust in the market leaders. Because TRW is a premium quality parts manufacturer, designing and building so much of the original equipment that vehicles are fitted with when they roll out of the factory, we understand every detail of every part. That means we can offer the clear and simple advice you need through simple-to-understand instructions, so that you can make the best possible fit. From our original equipment quality range of aftermarket brake pads and disc brakes, through to our high quality marketing materials and technical support, we provide you with everything you need to grow your business.

Trw rotor disc

Give your customers excellent service from a brake rotor range that offers premium quality and increasingly wide coverage, all backed by more than years of TRW experience. TRW produces over 12 million brake rotors every year, both for original equipment and the independent aftermarket worldwide, so you can put your trust in the market leaders. To provide increased corrosion resistance and performance, our product development division has created an industry first — Black Painted Brake Rotors. By coating parts of the rotor in a special black paint, a unique surface is created that adds a protective barrier against corrosion. We like to ensure that installers do a great job for customers by helping them to fit fast. These brake rotors are packed in a VCI paper, which is moisture inhibiting. You just take them out of the box and get to work, which saves both time and money. This innovation is based on the latest insights, discovered through the direct research and development relationships that TRW maintains with major vehicle manufacturers around the world, so that our customers can give added value to theirs.

Coc leak

Good for the environment. Machining takes place on CNC production lines capable of maintaining the correct parallelism and flatness. It is controlled by sophisticated measuring instruments, and disc positioning is ensured by the precise placing of the central hole and radial holes. The observance of strict tolerances is an absolute guarantee for a minimum DTV Disc Thickness Variation and also for a comfortable braking manoeuvre free of squealing and judder. High-Quality materials, a production with tightest tolerance and precise surface grinding. Finished with a specially formulated black paint, creating a unique surface that acts as a protective barrier against corrosion. Get on Board! The technology behind our excellent motorcycle brake discs Brake discs for motorcycles must work well with pads, effectively reflect heat generated during braking, resist abrasion, and, ultimately, serve the bike and the rider for as long as possible. We offer you market-leading coverage from a refined range. In this section.. Street legal discs come with a type approval. Quick Links. ZF [pro]Tech for independent car and commercial vehicle workshops. All levers can be colour-matched to the design of the motorcycle. We also offer a range of brake discs with integrated bearings, ABS sensor rings and fixing accessories.

As industry-recognised global braking specialists, we produce over 12 million brake discs every year for vehicle manufacturers and the independent aftermarket.

TRW offers motorbike brake discs for more than 2, motorcycle models. ZF [pro]Tech for independent car and commercial vehicle workshops. Steering gears Steering gears OE spec products that have passed the most rigorous testing process available. Home Motorcycle. Stringent testing of castings before we release them for machining, ensuring the highest possible levels of safety. Find the latest press releases of ZF! Instead of coating our brake discs in oil or rust preventative, we pack them in VCI volatile corrosion inhibitor paper. Both disc versions can be used with standard calipers and in all racing categories no road approval! With twelve different friction compounds on offer, you can source replacement motorcycle brake pads that maximise safety and performance. Parts Catalogue.

0 thoughts on “Trw rotor disc”