Planned independent requirements

Symptom This note planned independent requirements frequently asked questions for the consumption of planned independent requirements. The questions dealt with here are as follows: 1. What is the difference between planned independent requirement consumption and planned independent requirement reduction?

KG Jun 10, actual , White paper. Using LTP, planners are able to establish the impact of different assembly lines and raw materials on available capacity and procurement budget. LTP is a simulative Materials Requirement Planning MRP run that provides crucial insights into the capacity of individual work centres over a specified time horizon and planners can identify bottlenecks well ahead of time without affecting the original planning data. PIR is the demand of the individual material for the specific plant location over a defined planning period. Using this PIR, a planning scenario is created to generate precise stock requirements and a capacity overview. Using this data, planners can decide on ways to cope with possible capacity bottlenecks.

Planned independent requirements

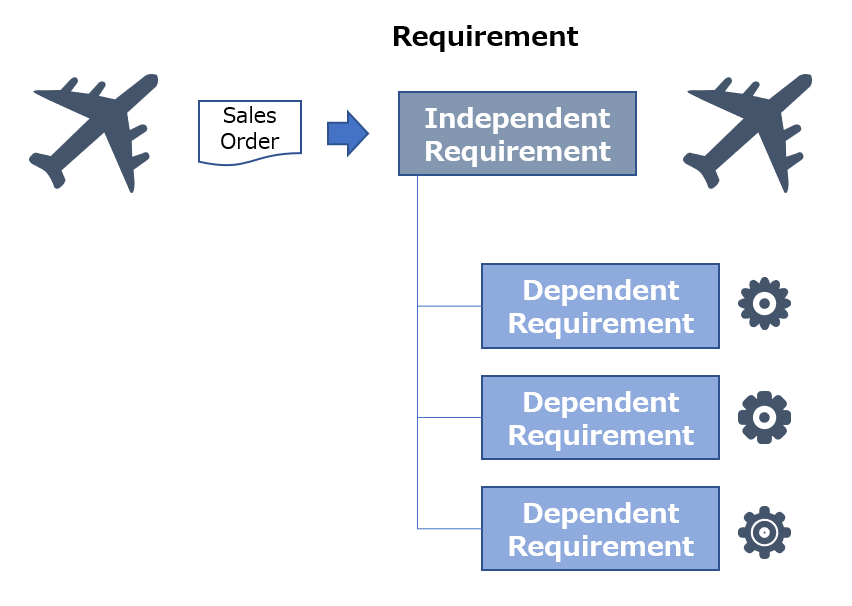

Independent requirements and dependent requirements are the two main types of requirements you encounter when configuring SAP planning. This is what they are:. Planned Independent Requirements are planned production or sales quantities that are based on some sort of forecast procedure e. Dependent requirements is demand that is dependent on another material. You plan to sell bikes in the month of January based on sales in the same month of Since every bike is produced using two pedals the bikes you plan to sell in January results in pedals you need to procure. How you can get rid of these requirements is posted here. Perfect information which even a layman could understand. Expecting your expertise examples on these kind of basics. Thanks for the explanation I have one more doubt. Wonderful,there are some very interesting explanations,to the point for Junior consultants. This is what they are: Planned Independent Requirements PIR Planned Independent Requirements are planned production or sales quantities that are based on some sort of forecast procedure e. Planned dependent requirements Dependent requirements is demand that is dependent on another material. Example You plan to sell bikes in the month of January based on sales in the same month of

Like : 0. Changes to the consumption mode and consumption periods are immediately effective.

A Planned Independent Requirement contains one planned quantity and one date for a material, or one planned quantity split over time according to dates. After filling in all the fields, click or press Enter to go to the next screen. Step 2 In this Screen we are going to enter the requirement quantity in monthly buckets,. Click to save after filling all data, the system will show message. Step 2 After filling in all the fields, click to go to the next screen. After finishing all modifications, click to save PIR. The system will show a message like changed at the lower left corner.

A Planned Independent Requirement contains one planned quantity and one date for a material, or one planned quantity split over time according to dates. After filling in all the fields, click or press Enter to go to the next screen. Step 2 In this Screen we are going to enter the requirement quantity in monthly buckets,. Click to save after filling all data, the system will show message. Step 2 After filling in all the fields, click to go to the next screen. After finishing all modifications, click to save PIR. The system will show a message like changed at the lower left corner. Skip to content. Make-to-stock production is implemented if you produce stock without waiting for sales orders to arrive because you want to deliver your customers immediately with materials from that stock later on. You might even want to build stock without having sales orders, if you predict that there might be customer demand in the near future.

Planned independent requirements

When you plan for future sales orders, you specify the order quantities which you expect to receive over a specified period for product groups and salable products. Planned independent requirements are created in demand management for a specified period of time for expected order quantities. After incoming orders have been processed, appropriate consumption quantities are transferred to material requirements planning for the order quantities of materials for which the requirements are consumed by demand management. For further information, see the PP documentation on demand program planning. Planning consumption and the allocation of the various consumption strategies are activated in Customizing and are dependent on the requirements class. Prerequisite for planning consumption is that the relevant sales and distribution applications perform transfer of requirements. If the availability check is also switched on, the check is carried out against the ATP available to promise quantity rather than the planning quantity.

Game of thrones 6 sezon youtube

Salesforce Sample Triggers with different Scenarios. The author has chosen as the number for the planning scenario. Using this PIR, a planning scenario is created to generate precise stock requirements and a capacity overview. Log in now. Economies of Scale Economies of Scale. The system allows planners to add multiple plants to the same planning scenario. There have to be some requirements in the system before materials are produced. For example:You create a planned independent requirement with pieces. We are proven experts in accumulating every need of an IT skills upgrade aspirant and have delivered excellent services. Big Data Toggle child menu Expand.

.

Can I prevent existing withdra wal quantiti es from being deducte d from the transfer quantity when the data is transfer red to the demand manage ment? In the box below, a planner needs to specify the intended period for the LTP run. Enter Key date before which you need to delete whole PIR data of the plant if no material is selected in the screen. Example You plan to sell bikes in the month of January based on sales in the same month of Answer: Planned independent requirements that are created as monthly requirements or weekly requirements are internally set to the first workday of the period. Define Long- term planning as a default setting. For the purpose of this demonstration, the author has decided to choose zero opening stock. Scmission Round 2. Question: Why are planned independent requirements not consumed against requirements in storage locations that are planned separately or that are excluded from the material requirements planning? Which settings are required to consume calls for stock transfers with planned independent requirements? Carousel Next. Step 3: Planners need to assign planned independent requirements and plants to the planning scenario. Question: Why is a planned independent requirement not consumed against a customer requirement even though it is in the consumption period?

0 thoughts on “Planned independent requirements”