Pfd process flow diagram

Create powerful visuals to improve your ideas, projects, and processes.

This is a typical way to label a piece of equipment using its position in the process. This is not the only way to label equipment, but a very common way. We will stick with this in this class and you will likely see it very commonly. Generally, rather than using numbers, utility streams will be labeled using a certain descriptor. These streams are labeled in this way as the same type of stream will generally have the same conditions, and so this saves repeatedly specifying these streams with numbers. The legend should include everything to allow someone to read the PFD with no prior knowledge of the project.

Pfd process flow diagram

VP Online is the best process flow diagram software because it offers a rich set of powerful editing features and symbols that suit different industries and purposes. You can easily map out a process flow with drag-and-drop, and share your design with others through exporting and sharing capbilities. So are you ready to draw a process flow diagram PFD? Followings are some process flow diagram examples. Click on an image to preview, or click the edit button to start editing. More PFD diagram templates and examples are available within the process flow diagram tool. Take a look at how Visual Paradigm Online can help you create diagrams quickly and collaboratively. Create shapes and improve precisions in a single interaction. Apply different formats to make your design attractive. Integrate seamlessly with MS documents, spreadsheets and presentations to maximize productivity.

Overview Definition.

This guide is brought to you by Zen Flowchart, the simplest flowchart tool. A process flow diagram PFD is a type of flowchart that represents the integrity of equipment and plant operations. This graphic chart depicts a link among the principal equipment of a facility. Nevertheless, it does not cover minor details such as designations and plumbing. While its popularity in engineering is undeniable, PFD also flourishes in other fields. Business owners rely on PFDs to record, enhance, and set up operational processes. Many experts have long been familiar with process flow diagrams.

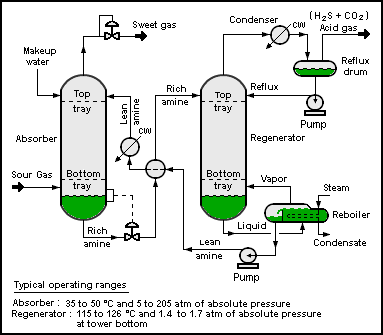

Normally the process scheme is a unified graphic representation of a system to be implemented, developed during the design phases and is divided into:. The Block Flow Diagram has the purpose of illustrating the logical flow of the processing phases of the product, highlighting the processing sequence, their concatenations and the types of treatment plant: each block represents a treatment unit of the process plant. The Process Flow Diagram examines the single unit or the plant itself, and it represents the main equipment, the connections between them pipes , highlights the main tools equipment, instruments, and valves , and the essential settings for a correct operation and a correct management of the plant itself, as the following nominal operate conditions:. Figure 1 Example of a measured and controlled Wessel with discrete electronic instrumentation:. A process flow diagram PFD shows, generally, only the major equipment used in a chemical process and the logic flow of the chemicals treated within the plant. PFDs are developed in the initial stages of plant engineering, or for training, maintenance and operation purposes, to outline the basic characteristics of the processes that have to be managed by the plant.

Pfd process flow diagram

Create powerful visuals to improve your ideas, projects, and processes. Work smarter to save time and solve problems. Helpful insights to get the most out of Lucidchart. Lucidchart is the best process flow diagram software available because it offers extensive features and shapes relevant to every industry trying to map out the process flow for any type of department, campaign, or means of standardization for a company or team. Learn the essentials of process flow diagrams PFD , including the history, benefits and helpful tips with this guide. Want to make a process flow diagram of your own? Try Lucidchart. It's quick, easy, and completely free. A Process Flow Diagram PFD is a type of flowchart that illustrates the relationships between major components at an industrial plant.

Discord canary download windows

Process flow diagrams PFDs are used in chemical and process engineering. Apply different formats to make your design attractive. Various PFDs for commercial processes are available in technology encyclopedias. Save Money, Reduce Hassle, and Get More Unleash your team's productivity by combining enterprise-class diagramming, whiteboarding, and data while saving 10x over Visio and Lucidchart! Process piping: Moves the product, usually fluids, between equipment pieces. It is possible to construct a PFD with process simulators or diagram software. We will stick with this in this class and you will likely see it very commonly. Each block can depict a single piece of equipment or a stage in a process. Documents Editor. This article includes a list of general references , but it lacks sufficient corresponding inline citations. This cookie is installed by Google Universal Analytics to restrain request rate and thus limit the collection of data on high traffic sites. Please make sure it's loaded before this plugin or use an asynchronous loader like requirejs. This guide is brought to you by Zen Flowchart, the simplest flowchart tool. PFDs are used for visitor information and new employee training. Chemicals Manufacturing.

A process flow diagram PFD is a graphical representation used to describe and document the flow and relationships between major components and processes in a system. PFDs are prevalent in engineering fields, particularly chemical engineering, manufacturing, and industrial engineering, but their usage spans a wide range of sectors, including business and software development.

Once it is installed, you can open the samples on this page directly in RFFlow by the links to the right of each picture. Read More. Work together to optimize processes and share feedback freely. Others Others. On a sophisticated PFD, you may need to use standard symbols such as ISO to clearly communicate and collaborate with diverse audiences such as other companies or agencies. Process Flow Diagrams PFDs are a schematic representation of the process, its normal operating conditions and its basic control. What's New Easy to administer and license your entire organization. In most cases, these textiles include garbage or recycled substances. Create Process Flow Diagram online. Composition of fluids Process stream names Connections with other systems What to exclude in a PFD Typically, these more detailed items are omitted: Pipe classes and pipe line numbers Process control instruments Minor bypass values Isolation and shutoff valves Maintenance vents and drains Relief valves and safety valves Code class information Other Types of PFDs When the diagram needs to show multiple unit processes at a plant, it becomes more of an overview, containing less detail. In both diagrams arrows show the flow of material and symbols show tanks, valves, and other equipment. Flow; driver type; suction and discharge pressures; temperature; shaft power; materials of construction. The Nirosa technical team works with the process flow diagrams in order to provide a clear and detailed study of the processes to be performed so that they can be analyzed for implementation.

0 thoughts on “Pfd process flow diagram”