New holland 469 haybine parts diagram

Log in Join. Search titles only. Search Advanced search….

Log in. Sign up. Home Forums Hay Talk Machinery. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding.

New holland 469 haybine parts diagram

Log in Join. Search titles only. Search Advanced search…. Today's Posts. New posts. Log in. For a better experience, please enable JavaScript in your browser before proceeding. You are using an out of date browser. It may not display this or other websites correctly. You should upgrade or use an alternative browser. Mowing New Holland haybine reel not turning very fast. Thread starter gemzacons Start date Jun 17, I'm mowing hay that doesn't seem thick enough to stop the reel spinning.

This is an older thread, you may not receive a response, and could be reviving an old thread. Josh Report to Moderator.

NH Haybine. Welcome Guest, Log in or Register. There is one coming up on an auction. I think this has 9' cut. What parts normally go bad in these.

By enrolling in, or otherwise participating in, the Program, you acknowledge that you have read, understood and unconditionally accept to be bound by the Terms. CNH reserves the right to modify these Terms, without further notice or compensation to you, and you waive any right to receive specific individual notice of such modifications. Any updates to these Terms will be effective immediately, and your continued membership in the Program constitutes your acceptance to such modifications. These Terms constitute a legally binding agreement between CNH and each individual who enrolls or otherwise participates in the Program. Accordingly, you expressly represent and warrant that you are eligible for the Program as described below and will otherwise comply with these Terms.

New holland 469 haybine parts diagram

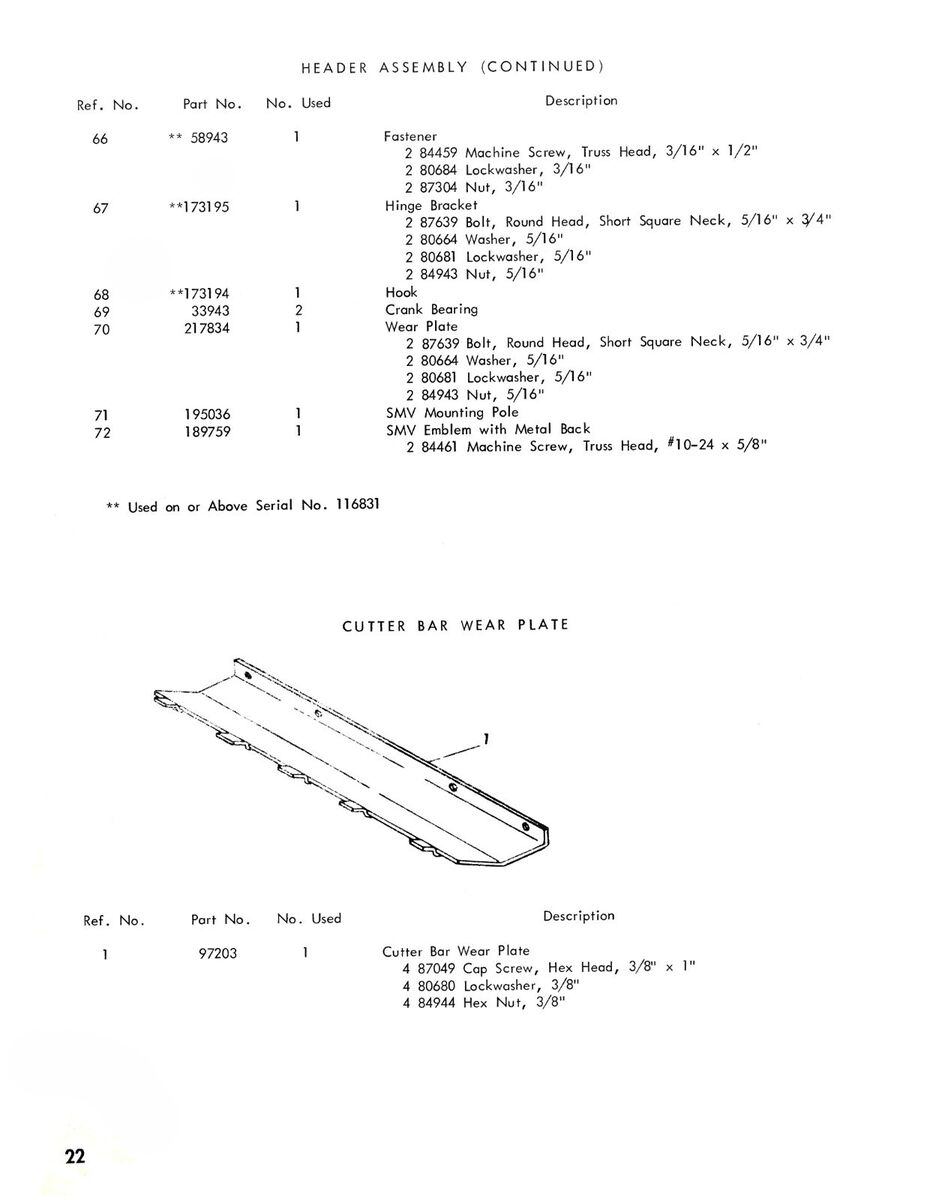

We want to help you find your parts! If you have questions or need help finding your part feel free to call our Parts Helpline. New Holland Haybine Parts. We can ship overnight or Ground directly to you from the New Holland Warehouses. You can order online at our New Holland Parts Store or if you would like some assistance you can call our Parts Helpline at:

Maax duel shower door

The belt is supposed to slip if you get a heavy slug through the machine or what I was accustomed to was dirt from a groundhog hole making it plug. They may look good but I can guarantee you they are also worn in a similar manner, you just can not see it. AVS Forum. It's a NH model Search Advanced search…. The bearings in the yoke of the wobble drive is where the play is going to be. If the bearings are shot and the rolls are bad This will cause the wobble assembly to move up and down out of its level plane. It should be round and not elongated. If you do, the yoke will have play when you back together. If the bearing does not come out, remove the cap on top and take a shaft and drive it out of the yoke. Other bolts will not stay in and loosen causing the bushing to fail. Parts are still available from NH.

.

Come join the discussion about tractors, machinery, harvesting, soils, pests, ranching, reviews, accessories, classifieds, and more! I'm guessing your belt has slipped enough to have some wore spots and that's why it slips in light hay. Sign up. I'm only getting about 30 acres to a bushing. Usually the rubber tears out of the bushing and the sickle will start knocking. John Deere and its logos are the registered trademarks of the John Deere Corporation. This will cause the wobble assembly to move up and down out of its level plane. It's held on with just a single set-screw. Slip clutch bolts broke and were easily replaced. The pivot bolt from the wobble shaft to cutter bar liked to fall out. The steady rest bearing and support at the bottom of the yoke will also be loose. Grass is not wet and I'm not going very fast. New posts.

I consider, that you are not right. I am assured. I can prove it. Write to me in PM, we will talk.

Choice at you hard