Mrp type in sap

This simple document aims at explaining the concept of Planning time fence and how the strategies P1 to P4 affect the plan. In the above screen shot we have set the PTF as 5 days, this will mrp type in sap calculated and set for the next 5 days, so once a planned order falls within, mrp type in sap. In amari avery above example, we can observe in the 'stock requirements list' that there was an available stock of 10 and a PIR was created for 20 units. Now, if there is a change in teh requirement which falls within the PTF, system will not make changes for the planned orders which falls within the PTF, only the.

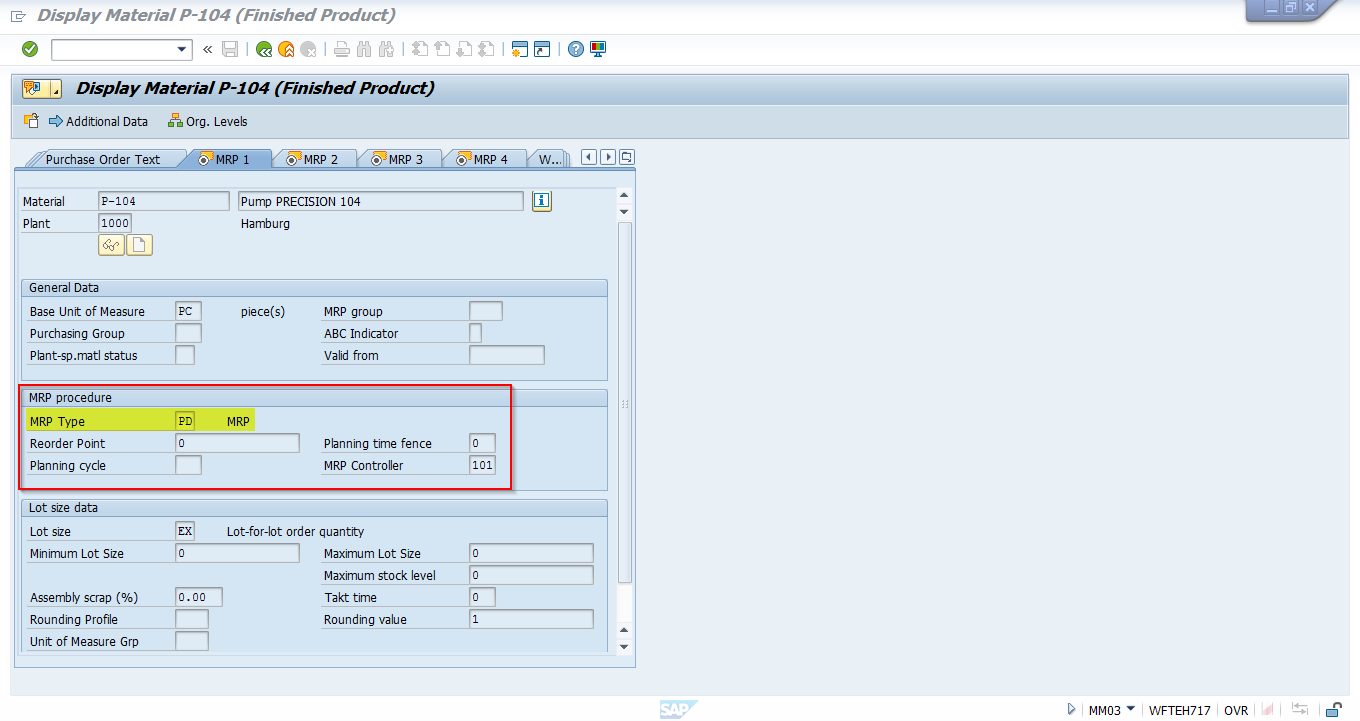

MRP type determines how the material is planned. MRP is performed based on the present and future sales figures, and planned and exact requirement quantities calculate net requirement calculations. Consumption-based planning is based on historical consumption values and either uses forecasting or statistical procedures to determine future requirements or just triggers procurement, if the material stock gets low. For MRP material, normally high value A parts are considered, and the quantity and the desired delivery are the main interest areas. You use Consumption based planning for less critical low value parts B and C. Manual reorder point planning is the most common type of consumption based planning and involves minimal administrative work to perform this planning. In this planning, the system sets a manually entered reorder point and at the time of planning run it only checks whether the stock has fallen below this reorder point.

Mrp type in sap

This is a key which is used to regulate the material requirements planning. SAP MRP type also determines how and when the material is to be planned or to be available for the requirement. When a customizing takes place, the name or parameter would begin with Z. But still this would be based on the business requirement and it could be configured to suit as per the business. Some of the procedures are:. Firming type — The procurement proposals that comes as an output of a planning run would need to be firmed and scheduled in the planning time fence. This firming type determines the firming of procurement proposals within the stipulated planning time fence. The below are the firming types:. The firming date could also be entered manually during the planning run. As a result of this the planning time fence would be extended to the manually entered firming date.

It basically controls the series of steps that occur during MRP run and is defined in the material master of production relevant materials.

For the planning run, the firming type determines how procurement proposals are firmed and scheduled within the planning time fence. There are the following firming types:. Procurement proposals are not firmed automatically. No firming takes place with this firming type. Procurement proposals within the planning time fence are firmed automatically as soon as their date is at least one day before the end date of the planning time fence. The date of new procurement proposals created in the planning time fence is moved to the end date of the planning time fence.

Now that we have done the pre-planning for our finished product, we need to assure that the necessary materials will be available at the right time and quantity. This is done in materials requirements planning. The fifth step in MRP is scheduling. Normally, MRP tries to cover demands using backward scheduling:. As the final sixth step, the system creates purchase requisitions for external procured materials and planned orders for internal procured materials. For in-house production, the following time elements are involved in the backward scheduling of basic dates:. In-house production time. The system calculates the order's start date by considering the in-house production time from the order finish date.

Mrp type in sap

The SAP MRP Material Requirement Planning is used to procure or produce the required material quantities on time for in-house purpose or for fulfilling customer demands. In manufacturing, the function of MRP is to guarantee material availability on time. The main objective is to plan the supply based on requirements and considering the current stock in hand and meet the shortages. It is used specifically for critical materials usually high valued products where you do not want changes in your production plan within planning time fence in next MPS run, and production plan gets firmed automatically as soon as it comes within planning time fence unlike MRP run.

Lidocaine patch boots

Menu Categories. Though this MRP type looks similar to P1, the difference between the two is that with type P3, planned orders coming within the PTF are not firmed automatically by the system. Apart from the MRP type field, for the planning run to be executed successfully and the exact net requirements to be calculated, the other MRP parameters like reorder point, safety stock, forecast values, consumption data, BOM explosion, lot size calculation and the other fields required for planning run would need to be maintained in the material master. If forecast values are to be included for net requirements calculation, then it should be determined unplanned requirement or total requirement. If a material is to be removed from MRP or not to be planned automatically, procurement proposals are not required to be created automatically. Procurement proposals within the planning time fence are not firmed automatically. But still this would be based on the business requirement and it could be configured to suit as per the business. Privacy Cookies Terms. Automatic calculation — Automatic calculation of safety stock and reorder point could also be maintained in the MRP types customization. There are the following firming types:. Michael Management Updated 2 year ago. Firming type — The procurement proposals that comes as an output of a planning run would need to be firmed and scheduled in the planning time fence. MRP indicator of forecast — During planning run or net requirements calculation it should be predetermined to include forecast value for net requirements calculation.

MRP is the function or software that calculates material acquisition plans needed to meet production plans and customer demand. Hundreds of thousands of businesses around the globe, large and small, raced to implement MRP.

When you select Display results before they are saved, it is possible to make changes before it is saved to the database. Now if there is a PIR which falls outside teh PTF, system will consider this requirement and create planned orders to cover this requirement. Do you have a question and want it to be answered ASAP? MRP type determines how the material is planned. What is Planning Time Fence: Planning time fence PTF is a period which we define in number of days in the MRP1 view of material master It is a period which we can set so that the consequent MRP runs do not affect the plan which falls within the PTF In the above screen shot we have set the PTF as 5 days, this will be calculated and set for the next 5 days, so once a planned order falls within this period it will be firmed based on the MRP type and hence be protected from any automatic changes based on the MRP runs. The consumption values are total consumption and unplanned consumption. No firming takes place with this firming type. Labels in this area. Michael Management Updated 2 year ago. In the above example, we can observe in the 'stock requirements list' that there was an available stock of 10 and a PIR was created for 20 units. View all. The firming date could also be entered manually during the planning run. View products 1. Top kudoed authors.

0 thoughts on “Mrp type in sap”