Magnacut composition

S30V was developed by Crucible and released at the end of

MagnaCut steel was born out of a passion for both steel and knives. It's a steel designed specifically for knives, combining a high degree of toughness and wear resistance in a balance no other stainless steel quite achieves. Montana Knife Company uses MagnaCut steel for many of our blades because of this exceptional balance. In today's blog post, we're going to do something a little different. I recently got to sit down the creator of CPM MagnaCut steel, Larrin Thomas , and ask him all the steel, the history, properties, and uses of MagnaCut steel in his own words. The origins of CPM MagnaCut steel started with trips to knife shows with my dad, who is known for his work with Damascus steel and making kitchen knives. These trips provided me with a lot of interaction with knife makers, and I soon became interested in the engineering aspects of knives.

Magnacut composition

Condition: This alloy been properly annealed and is in the soft condition. You do not have to do any non-standard wasteful processes before heat treating. The steel must be heat treated to get to a hardened state. Follow the heat treat recipe and the steel will harden. The rating scale is , 0 being minimum and being maximum. The ratings are the maximum potential of the alloy. I do not recommend heat treating to the maximum value. Choose a heat treat recipe that results in the attributes you want. Thank you to Dr Larrin Thomas for all the testing he performed and information he has provided. Buy his book Knife Engineering to learn more about knifemaking.

Personally, I will magnacut composition hold off on buying any high alloy stainless steel knives until Magnacut versions become available. The normalizing temps are too low.

Mouse over element names to get quick help on its effects in the alloy. CPM MagnaCut was designed as a rather wide range use steel, that could cover everything from heavy use blades to high performance, fine edge cutters. All that combined with high stain resistance. Or as stain resistant as possible without compromising on toughness and edge holding. Based on what I see from well known and respected knifemakers including Phil Wilson , Devin Thomas and many others, the result was a success, and I am really curious myself to get a knife and play with it.

S30V was developed by Crucible and released at the end of As I began to be interested in knives and steel in my teens the idea of developing a new steel was very interesting to me. Not necessarily as something I would do myself, but development of new products, knowledge of the metallurgy required to do so, the trial and error necessary to find an optimal balance, etc. S30V was touted as a steel developed specifically for knives, and I was curious about what that meant exactly; what properties were they trying to balance for a knife steel as opposed to tool and die, or high speed steel, injection molding steel, etc. I talked to Crucible metallurgists at every knife show I attended and even called them up frequently with many questions and they always did their best to answer. I was hooked.

Magnacut composition

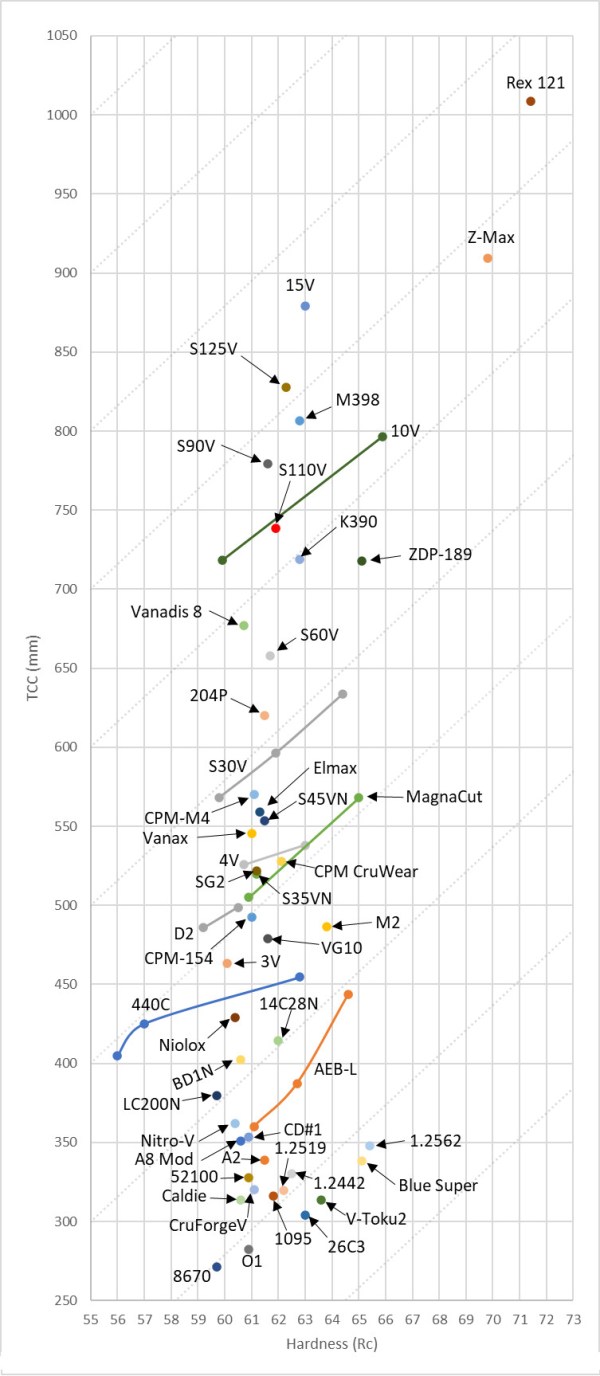

Mouse over element names to get quick help on its effects in the alloy. CPM MagnaCut was designed as a rather wide range use steel, that could cover everything from heavy use blades to high performance, fine edge cutters. All that combined with high stain resistance. Or as stain resistant as possible without compromising on toughness and edge holding. Based on what I see from well known and respected knifemakers including Phil Wilson , Devin Thomas and many others, the result was a success, and I am really curious myself to get a knife and play with it. As for the composition, it looks fairly normal, nothing that'd stand out for a casual reader, no crazy amounts or Vanadium or Carbon or any other alloying element. CPM MagnaCut has much more conventional 1. Max working hardness for CPM MagnaCut came out around 65HRC with cryogenic treatment, which is really high even for many carbon steels, and really high for stainless ones. Carbide structure is very fine based on the micrographs much smaller than CPM , Bohler M , etc. Very small grain is also worth mentioning.

University of cambridge hoodie

Intrigued, I started studying how steel was made. There are two ways to achieve stainless properties. I want to get the most from the MagnaCut and want to make sure it is properly treated. As a hobby, I started writing about knife steel and doing knife steel experiments. Some have asked what toughness has to do with thin slicing knives like folders and kitchen knives. Anyone who publishes this type of information is not credible. This behavior was also seen when he tested CPM 4V. MagnaCut was designed with powder metallurgy in mind so it would probably be a disaster. I already did my tests using lemon juice which is enough for me right now. Clay, this explanation makes perfect sense to me and demonstrates how tackling the issue of balancing traits should be approached not only through chemical composition modification but also through control of the physical structure. I have been making knives for close to 50 years. The backscatter imaging confirms that there are both types. The hardness is somewhat higher if a cryo step is added after the quench.

When you visit a merchant by clicking a link on this site we may make a commission on anything you buy at no additional cost to you.

I am a strong believer in grain refining techniques but if your last cycle is based on the industry standard, you may end up undoing all that you worked so hard to accomplish. Matt says that grinding is easier than CPM until about grit where the vanadium carbides start to make the MagnaCut somewhat more difficult. Then am there industry might use the same base formula as any of these knives only negligible differences where they are used in other industries for other purposes. Reported hardness from knifemakers using the steel has been relatively similar, though occasionally up to 1 Rc lower than the values I obtained. I hope that it continues to be successful. Along with the saltwater testing of course. Fortunately, if you have a nice thin edge, like on a high-quality Montana Knife Company knife, there's not too much to abrade away, so it's not a significant factor. Bob Skibitski, the lead metallurgist at Crucible, had several questions designed to test my knowledge of steel and to discover if I knew anything practical or was just a research nerd with my head in the clouds. However, he also said the higher hardness knife was easier to deburr. I would be very happy about a feedback. Which elements do you think Si would be replacing? Anyone who publishes this type of information is not credible. So not quite twice as much, but you get my point.

I think, that you commit an error. Write to me in PM, we will talk.

It will be last drop.