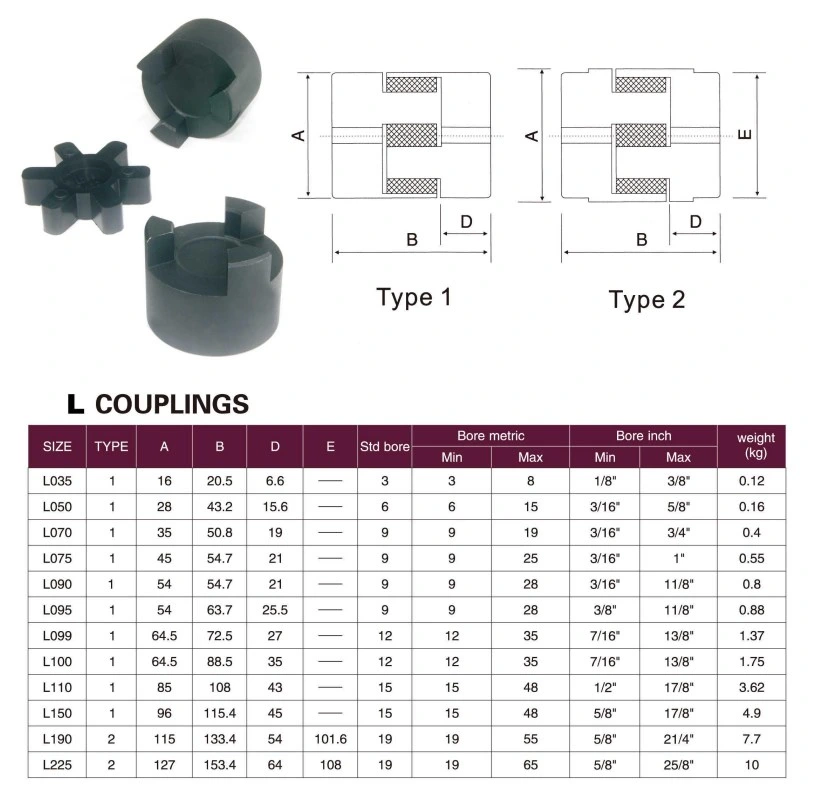

Lovejoy coupling size chart

The goal of this handbook is to assist you with the process of sorting out the myriad of coupling styles that exist to select the one best suited to your application.

Safety Warning When using Lovejoy products, you must follow these instructions and take the following precautions. Failure to do so may cause the power transmission product to break and parts to be thrown with sufficient force to cause severe injury or death. Refer to this Lovejoy Catalog for proper selection, sizing, horsepower, torque range, and speed range of power transmission products, including elastomeric elements for couplings. Follow the installation instructions included with the product, and in the individual product catalogs for proper installation of power transmission These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion power transmission applications.

Lovejoy coupling size chart

.

The torque rating can be used as a peak load or cyclic high and not always as the normal operating torque.

.

The goal of this handbook is to assist you with the process of sorting out the myriad of coupling styles that exist to select the one best suited to your application. This handbook is not a textbook. There are several of those in print which do a great job and are very useful for coupling designers. What we are attempting to do is to provide down-to-earth useable knowledge. We want to arm you with information that you need to utilize the variety of styles that exist in flexible couplings to your best advantage and solve real world problems.

Lovejoy coupling size chart

Jaw Type Couplings Catalog pdf. Stainless Steel Jaw Sell Sheet pdf. Jaw Coupling Selection Worksheet pdf. Urethane — Greater torque capability than NBR 1. Good resistance to oil and chemicals.

5e psychic lance

Those are in addition to the usual gear coupling requirements. The fasteners are tightened so make a high friction joint to avoid loading the bolts in shear. The donut is fastened to the inner or cylindrical hub by radial fasteners. Note that the geometric configuration of the coupling will determine the loading. The key is the main means of torque transfer, and may be either a loose or interference fit. Elastomers for Donut Type couplings. Noise reduction can be an advantage in certain applications, such as HVAC systems. Its design is simple, usually involving only three parts. The Grid coupling teeth do not mesh between the hubs, therefore, if the grid spring were to fail the coupling would no longer transmit torque. Bigger Than Size 7. Hystersis, a characteristic exhibited by rubber with binders, allows the elastomeric material to adsorb dynamic energy. SET SCREW: A headless screw, with hexagon shaped socket, used over a keyway to keep the key stock in place and prevent the coupling from moving axially along the shaft. Various pressure angles were used that walked the line between life and strength.

Each hub includes a set screw unless noted , which bites into your shaft to hold the coupling in place.

Note: Information supplied should include all operating or characteristic values of connected equipment for minimum, normal, steady-state, transient, and peak levels, plus the frequency of their occurrence. Follow the installation instructions included with the product, and in the individual product catalogs for proper installation of power transmission In fact, the maximum outer diameter of the flange on flanged sleeve couplings is partially determined by the needs of space for bolts and surface for friction. Nominal sizes are not just any number, but are chosen from a list of preferred numbers. These are attributes that affect the type of coupling best suited for an application. Couplings needing higher strength or hardness for greater wear resistance are made from AISI which also can be bar stock or forging. Speed is a problem for elastomeric couplings. Other specifications could allow body fit bolts to carry the load in shear, although from an engineering standpoint the concept of carrying load on bolts in shear is not favored. At this point, the nominal torque requirements of the system times an application factor that could be used to select the coupling. This type of elastomeric coupling transmits torque between hubs through an elastomeric element in-shear, but transmits torque from hub to element and back again by compression between hub teeth and intermeshing teeth formed into both ends of the element. Each type of coupling has some advantage over another type.

Bravo, what phrase..., an excellent idea

Excuse, not in that section.....