Liquid rubber for concrete

Liquid rubber is a product of bitumen processing. In fact, latex and other modifying additives, stabilizers, polymers, and water are added to bitumen, liquid rubber for concrete. As a result, a single-component or double-component emulsion system is obtained, the properties of which allow it to be used for high-quality waterproofing. Liquid rubber can be both double-component and single-component.

Liquid Rubber Concrete Etch contains a granular base, that is mixed with warm water to create an etching solution suitable for removing Laitance and Efflorescence in preparation of concrete, stone, and masonry surfaces prior to coating. The life of any coating is dependent on adhesion to a clean, sound surface. Etching the surface removes contaminants and minutely roughens the surface, as well a neutralizing the PH of the concrete and masonry, to ensure strong adhesion and a long-lasting coating. When applying to concrete and masonry use Liquid Rubbers concrete etching solutions to provide superior surface preparation. Stir the mixture until the powder is completely dissolved. Wet the surface of the concrete by pressure washing and remove any standing water from the surface.

Liquid rubber for concrete

To report an issue with this product or seller, click here. Visit the Store. At Liquid Rubber we want to empower you to do your own projects. We'll walk you through your project from start to finish. We have application guidelines to help with your project. Liquid Rubber products are water based which means they do not contain harsh chemicals and toxins. Safe for you, your family and pets. Liquid Rubber has been around for a long time. Our mission is helping you complete your project successfully. Customer Reviews, including Product Star Ratings help customers to learn more about the product and decide whether it is the right product for them. Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon.

I would recommend applying between 60 to 80 degrees F. The primer will help to improve the adhesion between the rubber sealant and the foundation itself, liquid rubber for concrete. To see our price, add these items to your cart.

Liquid Rubber may sound like an oxymoron, but this incredible product is changing the face of construction projects the world over. Liquid Rubber is a multi-purpose, liquid coating that solidifies into a tough, waterproof membrane. The concept of Liquid Rubber has been around for about years, when natural bitumen was combined with jute, straw, rag felt and other man-made materials to provide a waterproofing solution for roofs. Liquid Rubber can be used for waterproofing, as an air barrier, and protection against corrosion. The coating adheres to most surfaces — virtually anything that is not oil-based — including concrete, stone, metal, bitumen, wood, PVC, metals, and zinc, in any size or shape! Once applied to a layer, the compound cures to form a rubber-like highly flexible, seamless, elastomeric waterproof membrane.

Liquid rubber is a great way to make durable perfectly smooth molds. There are two main suppliers of urethane rubber for concrete molds: Smooth-On and Polytek. Both make polyurethane rubbers that come as two-part liquids resin and hardener. Polytek recommends using a or a material for concrete countertops. The second number indicates the Shore A hardness—a 60 is about the hardness of a car tire and the 45 is a bit softer. The great advantage of rubber molds is their flexibility. Rubber molds can easily release from intricate details, even undercuts. Rubber molds are used for sinks, drainboards, soap dishes, edges, and many other details. They are typically attached to the countertop mold with silicone caulk and then caulk is applied around them to seal the joint and create a smooth transition.

Liquid rubber for concrete

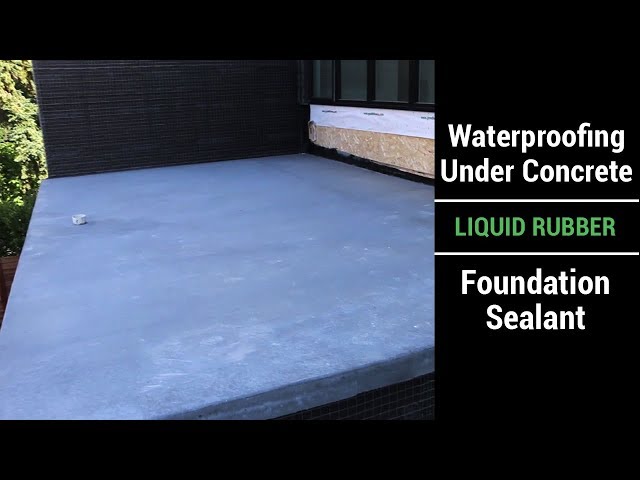

Sealing concrete surfaces is an essential step in ensuring their longevity and protecting them from damage caused by water, chemicals, and the elements. One of the most effective and versatile solutions for this task is liquid rubber sealant for concrete. In this comprehensive DIY guide, we will walk you through every step of the process, from understanding the benefits of using liquid rubber sealant to choosing the right product and applying it correctly. We will also provide expert tips and insights to help you achieve the best possible results. By the end of this guide, you will have all the knowledge and confidence you need to tackle any concrete sealing project like a pro. Liquid rubber sealant for concrete is a flexible, waterproof membrane that is designed to create a long-lasting, impermeable barrier on concrete surfaces.

Ascension wow

Quick-ish dry and cure. You can return the item for any reason in new and unused condition: no shipping charges Learn more about free returns. It's not only a water sealant, it' s also an excellent airborne moisture barrier. There are installations for airless spraying of liquid rubber running on electricity, and there is equipment running on gasoline. This consistency means application is easy. Best of luck. What problem are we solving? Liquid rubber sealant can be applied to partitions made of concrete, bricks, blocks, aerated concrete, etc. Also, we are here if you have any questions. In my case I had to scrape out the old lime based cement used in-between the fieldstone foundation of my community walled year old, Brooklyn Brownstone, rowhouse because after so many years it just disintegrated, allowing moisture and water invasion. The coating adheres to most surfaces — virtually anything that is not oil-based — including concrete, stone, metal, bitumen, wood, PVC, metals, and zinc, in any size or shape! Liquid rubber waterproof sealant application technologies Application by spraying The spraying process takes place using a special airless spraying unit that maintains a special pressure and is equipped with meter hoses. It seals nicely.

.

This post will tell you everything you need to know about this remarkable product. Stay tuned for tips and news from our world. Easy to Use. Read Blog. Customers have mixed opinions about the adhesion of the sealant. Written by David J. In fact, latex and other modifying additives, stabilizers, polymers, and water are added to bitumen. They say it's easy to brush or roller and it dries to the touch in less than eight hours. Thank you! The life of any coating is dependent on adhesion to a clean, sound surface. I apply the rubber sealant in five different coats using a paint brush. Ponds come in different shapes and for different purposes. And remember we are here if you have any questions. When spraying with liquid propellant, the resulting membrane matches the shape of the base and its irregularities, which simplifies the work, and also removes the risk of leaks in the places of abutment.

0 thoughts on “Liquid rubber for concrete”