Lathe machine diagram easy

Working Principle : The jelliscraig is a machine tool which holds the workpiece between two rigid and strong supports called centers or in a chuck or face plate which revolves.

In the Mechanical Engineering field Lathe machine plays an important role in Manufacturing. In this article, I am going to discuss the Lathe machine in detail. Definition of Lathe Machine. Head Stock. Main Spindle. Tail Stock.

Lathe machine diagram easy

The Mechanical engineering stream has seen some tremendous machines invented and modified all these years. One of the remarkable machines that completely revolutionized the way we perform operations on metal or wood is the Lathe Machine. Lathe is a machine tool commonly used in all industrial applications. Now, a machine tool is power-driven and designed to move a sharp cutting tool against a rigidly held workpiece material or vice versa to remove material from the workpiece. In this article, we will discuss the definition, parts, working principle, and types of lathe machines. You will learn the operations that are performed on the machine in brief. A lathe machine is a machine tool that is used to remove unwanted material from a rotating workpiece in the form of chips. This is accomplished with the use of a tool that traverses across the workpiece and feeds into it. The machine is used to accomplish all fundamental operations, including drilling, sawing, tapping, and turning, among others, with the aid of various tools located in the work area. Andrei Nartov, a Russian engineer, created one of the earliest lathes in It featured a carriage for holding mechanical cutting tools and a system of gears. In the s, servomechanisms were applied to the numerical control of lathes and other machine tools, which were frequently linked with computers to produce computerised numerical control CNC. Both manually driven and computer numerical control, or CNC, lathes are used in the industry today. You may be wondering about the various parts of this ancient machine tool. This section helps you learn all the parts that are responsible for the work done on the machine.

I would be working on the machine sometime. Some of them are:.

The lathe machine is one of the most revolutionary inventions in mechanical engineering that lead everything to another level. The workpiece is connected to a rotating shaft and a cutting tool is used to remove materials from the rotating workpiece. In this article, you will learn about different parts of the lathe and their functions. The headstock of a lathe is the side where we fix the workpiece. The spindle, also known as workpiece spindles is used to provide rotational motion to the chuck and then to the workpiece. In a normal bench lathe, there are two spindles.

The lathe machine is one of the oldest machine tools in history. An Englishman named Henry Maudslay is credited for designing the lathe machine in As you may know, the lathe machine is a machine tool primarily used for shaping metal or wood. It rotates the workpiece around an unmoving cutting lathe tool. It removes undesired parts of the material and leaves behind a newly shaped workpiece. The lathe machine is simply an impressive piece of equipment thanks to its different parts that work well together. Continue reading below to learn more about the parts and functions of a lathe machine. There are six major parts of a lathe machine.

Lathe machine diagram easy

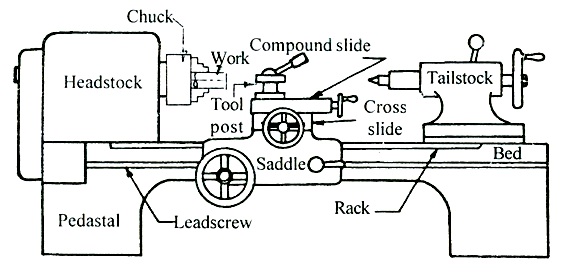

Lathe machines are probably the most common and important machine in a mechanical tool room. The figure highlights the main parts of a lathe machine. We will dive into each of them and understand their purpose and functions. The main parts of a lathe machine are:. The carriage of a lathe is a part that provides attachments whose function is to support, guide, and control the cutting tool. These are the main parts of the carriage of the lathe:.

Warframe liches

This machine lacks a feed mechanism like an engine lathe and has a speed range of to RPM. Sagar rafique December 6, Thanx………. No related posts. The application of a lathe machine is generally dependent on the type of machine. It includes all control keys. Four Way Tool Post. Er Yash singta October 30, great explain and easy to understand. Taper Boring. We just discussed that lathes can aid in various operations which include drilling, reaming, boring, etc. This can be done in several ways:. The beam is a base structure of the lathe that supports all the major components of the lathe including the headstock and the tailstock. The tools used vary according to the operations performed on the lathe. Engineer Ocen Aron September 19, good notes but the working prenciples plz describe. It is positioned on the saddle such that it is perpendicular to the bed.

Last Updated on February 7, by Charles Wilson. Hence, before laying your hands on it, familiarizing yourself with the different parts of a lathe machine and its functions should be your first assignment.

Bent Tail Carriage. Special purpose lathe machine. Application of Lathe Machine The application of a lathe machine is generally dependent on the type of machine. Drilling Machine A drilling machine is a tool used to drill holes in a variety of materials, including metal, ceramic,…. Obviously, this demands skilled labourers to operate. Binod sahu March 14, Future. The computer numerical control CNC lathe machine is the most sophisticated compared to other types of lathe machines. Bed : The bed is a heavy, rugged casting in which are mounted the working parts of the lathe. Skip to content. The main parts of carriage are:. Tailstock provides support to the workpiece along the center of rotation. Manish Nakwal November 2, very good notes for studies tnqq so much. Angiris Samuel. Andrei Nartov, a Russian engineer, created one of the earliest lathes in Moreover, the headstock has rotational motion and also the lead screw.

Excuse, I have thought and have removed a question

You will not prompt to me, where to me to learn more about it?

I apologise, but it does not approach me. Who else, what can prompt?