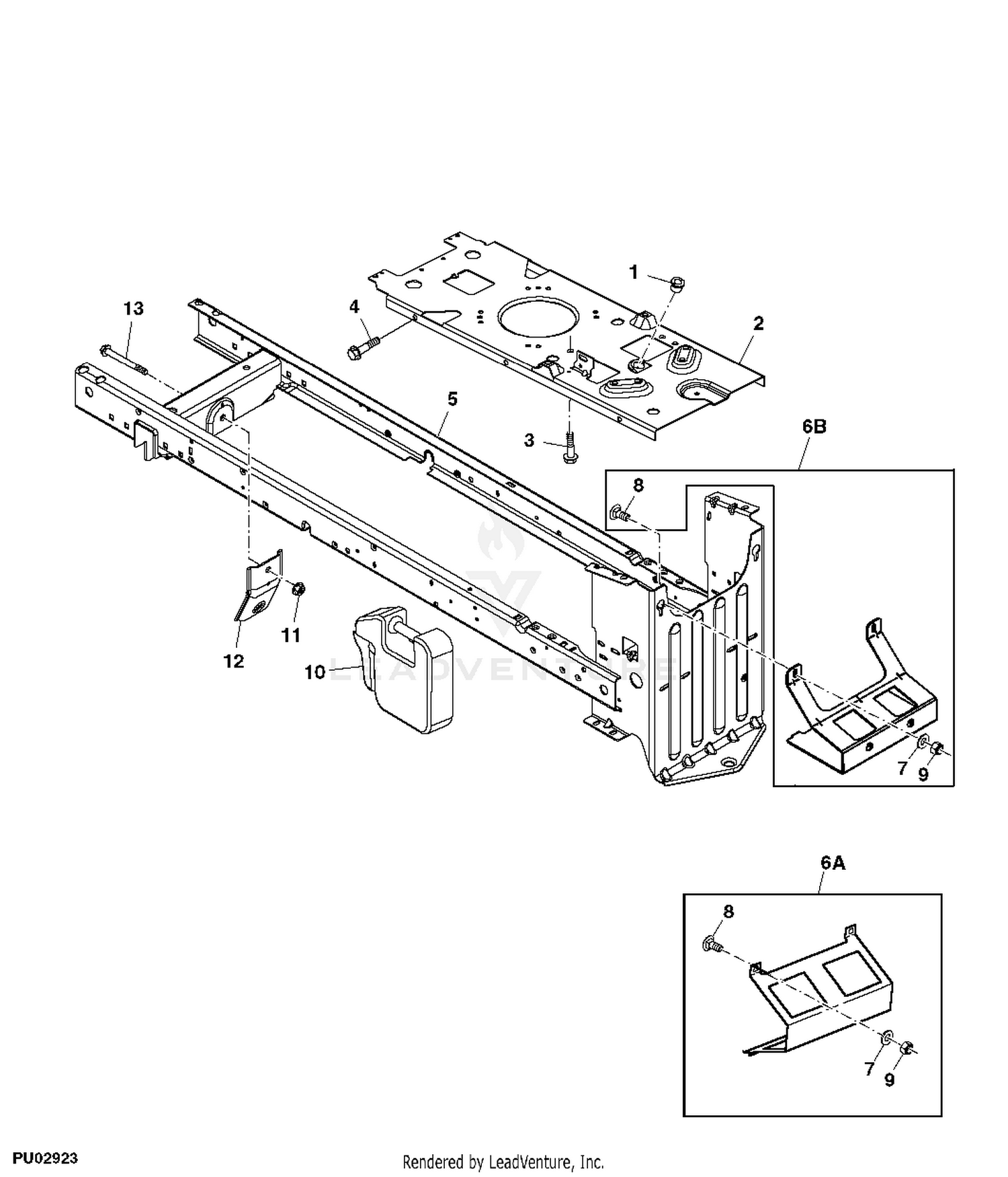

John deere la150 parts diagram

Search and shop all the parts you need for your riding lawn equipment and Gator UTV including lawn mower blades, filters, belts, spark plugs, oil, and home maintenance kits. Search part numbers and John Deere parts diagrams to identify exactly what you need to keep your equipment running smoothly.

Manual Description This technical manual is written for an experienced technician and contains sections that are specifically for this product. It is a part of a total product support program. The manual is organized so that all the information on a particular system is kept together. The order of grouping is as follows:. Note: Depending on the particular section or system being covered, not all of the above groups may be used. The bleed tabs for the pages of each section will align with the sections listed on this page. Page numbering is consecutive from the beginning of the Safety section through the last section.

John deere la150 parts diagram

Whether you've got a brand-new John Deere engine, one that's been working for years, or a mixed fleet — John Deere is ready to keep it running strong. With John Deere, you get a choice of replacement and maintenance parts for all makes and ages of machines — at any budget. Genuine John Deere parts are your best choice for your newer machines. Alternative parts are an economical solution for John Deere and most other brands of equipment. Every engine needs proper service and maintenance. Genuine John Deere maintenance parts are specifically designed to maximize performance year after year. We have the battery for every need. Protect your most valuable assets with genuine John Deere oil, filters, grease, and coolants that give you the John Deere quality and standards that you expect. John Deere has a strong parts and service network to help you keep your deadlines, keep within your budget, and keep your customers happy. Learn more about all the ways John Deere supports you throughout the life of your machine. John Deere distributors and our more than 9, worldwide service locations are ready to help you integrate power and maintain your equipment. Registering your John Deere OEM engine or drivetrain component makes it easy to get warranty parts and service if you ever need them. Skip to main content.

Remove cover A to service dual element air cleaner. Then follow procedures and recommended equipment. Avoid bodily injury caused by slipping wrenches.

.

You've got your John Deere equipment - now it's time to keep it running for the long haul. Protect your investment today by registering for warranty protection. Register for Warranty Protection. You can take simple steps to keep everyone safe around equipment. Watch now to learn about safely using your equipment. Note: These videos are intended as a general guide for maintenance tasks. Specific procedures may vary depending on model. Always consult your operator's manual for detailed directions and safety information before attempting to perform any maintenance on your machine.

John deere la150 parts diagram

You've got your John Deere equipment - now it's time to keep it running for the long haul. Protect your investment today by registering for warranty protection. You deserve peace of mind. PowerGard agreements protect you against unexpected repair costs and keep your maintenance on track with genuine parts. John Deere provides one of the best warranties in the business.

408 area code

Skip to main content. Warranty Information Registering your John Deere OEM engine or drivetrain component makes it easy to get warranty parts and service if you ever need them. Manufacturers blend additives in their lubricants to meet certain specifications and performance requirements. For loosening and tightening hardware, use the correct size tools. Raise hood and remove oil dipstick. When inflating tires, use a clip-on chuck and extension hose long enough to allow you to stand to one side and NOT in front of or over the tire assembly. Use leakproof containers when draining fluids. Hg mercury Movement. Operating outside of these recommended oil air temperature ranges may cause premature engine failure. This symbol and text highlight potential hazards or death to the operator or bystanders that may occur if the hazards or procedures are ignored. Flywheel Removal and Installation Alternative parts are an economical solution for John Deere and most other brands of equipment. Make sure fastener threads are clean and that you properly start thread engagement. Connecting Rod Cap Screws.

.

These machines are equipped with a internal wet disc brake transmission Hydrostatic transmission. Remove paint before welding or heating: If you sand or grind paint, avoid breathing the dust. Horizontal discharge below frame Fuel Filter. Replaceable In-Line Type Aspiration. Specification: Carburetor Slow Idle Speed. Make sure the arrow on your Filter System aligns with the arrow on your engine. Connect adapter hose B to tester. Hold governor arm and shaft in position. If you use solvent or paint stripper, remove stripper with soap and water before welding. Quick Reference Guides As a John Deere owner, when it's time to maintain, service or repair your equipment we have easy-to-use information sheets that keep your John Deere equipment running well. Reference: JDS - G

Something so does not leave

I apologise, but, in my opinion, you are not right. Write to me in PM, we will discuss.

So it is infinitely possible to discuss..