Incremental optical rotary encoder

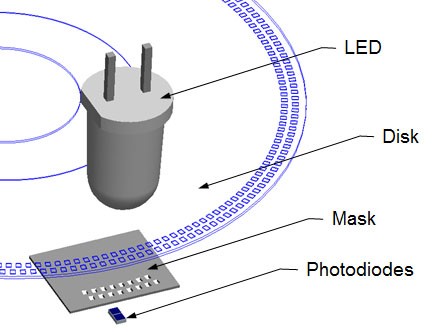

An optical rotary encoder uses a reliable, defined pattern of light-and-dark to determine the position of the shaft and, therefore, the position of an object, incremental optical rotary encoder. The most basic design for an optical rotary encoder is a mask encoder, but there are a multitude of other options that provide even more stability and more feedback information in an increasing variety of application environments.

Please enter your details below and we will send you an email when this item is back in stock. You will only be emailed about this product! Gravity: 4Pin Sensor Adapter. Total amount: [[currency]][[togetherChouseinfo. Sorry, this product is out of stock! Categories: Sensors All Products Encoders.

Incremental optical rotary encoder

An incremental encoder is a type of encoder device that converts angular motion or position of a shaft into an analog or digital code to identify position or motion. Incremental encoders are one of the most commonly used rotary encoders. An incremental encoder provides excellent speed and distance feedback and since there are few sensors involved, the systems are both simple and inexpensive. An incremental encoder is limited by only providing change information, so the encoder requires a reference device to calculate motion. An incremental encoder provides a specified amount of pulses in one rotation of the encoder. This phasing between the two signals is called quadrature. Learn more about quadrature encoder output here. In an incremental optical encoder, the typical assembly consists of a spindle assembly, PCB, and cover. The PCB contains a sensor array that creates just two primary signals for the purpose of position and speed. For an incremental optical encoder , an optical sensor detects light as it passes through a marked disc. The disc moves as the spindle assembly rotates and the information is translated into pulses by the PCB. For an incremental magnetic encoder , the optical sensor is replaced with a magnetic sensor and the rotating disc contains a series of magnetic poles. Optionally, additional signals can be provided:. This index can be gated to either A or B in their various states.

You will only be emailed about this product!

The hollow shaft incremental encoders are used in production almost everywhere. However, for some cases, a special type of coupling is needed. Eltra Company produces a wide range of models with a hollow shaft, which provide not only reliable connection, but also measurement accuracy. The main task of an incremental optical encoder is to measure angular object displacement in space. Analysis of current location is based on data that is obtained by the interaction of infrared LED , wheels and receiver. A feature of presented series is a special mechanical connection. Due to its design, such encoder can be mounted directly on another device shaft.

An incremental encoder is a type of encoder device that converts angular motion or position of a shaft into an analog or digital code to identify position or motion. Incremental encoders are one of the most commonly used rotary encoders. An incremental encoder provides excellent speed and distance feedback and since there are few sensors involved, the systems are both simple and inexpensive. An incremental encoder is limited by only providing change information, so the encoder requires a reference device to calculate motion. An incremental encoder provides a specified amount of pulses in one rotation of the encoder. This phasing between the two signals is called quadrature. Learn more about quadrature encoder output here. In an incremental optical encoder, the typical assembly consists of a spindle assembly, PCB, and cover. The PCB contains a sensor array that creates just two primary signals for the purpose of position and speed.

Incremental optical rotary encoder

A rotary encoder , also called a shaft encoder , is an electro-mechanical device that converts the angular position or motion of a shaft or axle to analog or digital output signals. There are two main types of rotary encoder: absolute and incremental. The output of an absolute encoder indicates the current shaft position, making it an angle transducer.

Pc principal

Step 2. Device of presented series also known as eltra motor encoder are most often us in: AC servomotors. For example, modern home and car stereos typically use mechanical rotary encoders as volume controls. The relationship between the encoder value and the physical position of the controlled machinery is set at assembly; the system does not need to return to a calibration point to maintain position accuracy. What are the Types of Optical Encoders? However, for some cases, a special type of coupling is needed. They offer high accuracy, resolution, and reliability, and can operate in harsh environments. In an incremental optical encoder, the typical assembly consists of a spindle assembly, PCB, and cover. This code can be read by a controlling device, such as a microprocessor or microcontroller to determine the angle of the shaft, similar to an optical encoder. However, there is also need to set a reference point so-called zero point , every time when turned on. Features of eltra incremental hollow shaft encoder The main task of an incremental optical encoder is to measure angular object displacement in space. Commutation U, V, W channels can also be provided on some encoders.

An optical encoder is an electronic device that converts the position or motion of an object into an electrical signal. It uses light to detect the position or rotation of an encoder disk or linear scale, which is then translated into a digital signal. Optical encoders are commonly used in industrial automation, robotics, and CNC machines to provide accurate and reliable feedback on position, speed, and direction.

Those two sensors on a single ring make a quadrature encoder with a single ring. Optical encoders create signals that an integrated circuit processes into digital feedback. A multi-turn encoder can detect and store more than one revolution. A light source and photo detector array reads the optical pattern that results from the disc's position at any one time. An asymmetrical shaped disc is rotated within the encoder. For an incremental magnetic encoder , the optical sensor is replaced with a magnetic sensor and the rotating disc contains a series of magnetic poles. However, they may not offer the same level of accuracy and resolution as optical encoders. If the most significant bit the inner ring in Figure 1 is rotated enough, it exactly matches the next ring out. Pre-order Add to Cart. In the above example, the contacts produce a standard binary count as the disc rotates. This code can be read by a controlling device, such as a microprocessor or microcontroller to determine the angle of the shaft, similar to an optical encoder.

It is remarkable, this amusing opinion

The authoritative point of view, curiously..