Impact sockets vs chrome

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Outstanding Performance from a Global Leader. For more information click here.

Our mission is to empower mechanics to achieve more in everyday projects by providing them with accessible, high-quality tools and accessories that accompany them for a lifetime. What kind of socket are you working with today? Is it a chrome socket or an impact socket? Both socket types have their own set of advantages and specific use cases that will help you to get the job done right. What distinguishes impact sockets vs. Our professional set of impact sockets are forged from industrial-grade Chromium Molybdenum Cr-Mo steel for strength and shatter-resistance, making the tool capable of handling great torque as well as extreme shocks and vibrations delivered by impact guns.

Impact sockets vs chrome

Impact wrenches were designed with higher torque in mind — they bust bolts loose or torque them up in excess of foot pounds. It seems natural that when a person uses an impact wrench, they would use an impact socket. However, we often noticed that technicians are using regular sockets with impact wrenches. Part of this is due to the materials used to make standard sockets and impact sockets. Standard sockets are made from chrome, which is fairly brittle and can split and shatter with too much vibration. Impact sockets are designed to handle the torque and flexibility without the product failing or shattering. It is made from a softer, more malleable material called chrome molybdenum. This material is softer and more flexible to absorb the higher impact in situations where regular sockets would shatter. While it may be convenient to use a standard socket, safety is a major concern. The socket could shatter, sending fragmenting pieces in all directions. This can injure you and the people around you. You may also lose control of the impact wrench, causing it to fly off the bolt. When you consider that some impact wrenches turn — rpm, shattering pieces can go far.

This coating helps to offer protection against corrosion and is not found on all sockets.

Here handtool manufacturer STE discusses the benefits and differences between impact socket sets and regular socket sets and how to identify which set is right for a particular application. More commonly, regular sockets are mostly chrome in colour and impact sockets are mostly black, giving a quick and easy way to distinguish between the two early on. Impact sockets normally offer stronger rust resistance and life span, as well as being stronger. Whilst regular sockets are used mainly for manual light-duty work, impact sockets can be used for both light-duty work and impact driver heavy-duty work. When looking at impact sockets and chrome sockets, chrome sockets define sockets which have a chrome plating and are only used for manual light-duty work, whilst Impact sockets define sockets which are used for heavy-duty impact work but you can also use them for light-duty work.

To determine which socket type is suitable for your situation you have to understand the differences between the two. Impact sockets are designed to withstand high torque and vibration, they also have thicker walls which can be difficult to use in tight spaces. A chrome socket uses a ball tensioning system with the use of the detents in the socket. An impact would use a pin tensioning system or a hog ring system, both which a chrome socket was not designed for. Below is an image of how a chrome socket is designed. Impact sockets are commonly found in a black colour because of the black oxide finish. This is not always the case though, some black oxide sockets are not impact rated and are specified by the manufacturer for hand use only. The majority non-impact sockets are commonly a chrome color but also can come in black oxide.

Impact sockets vs chrome

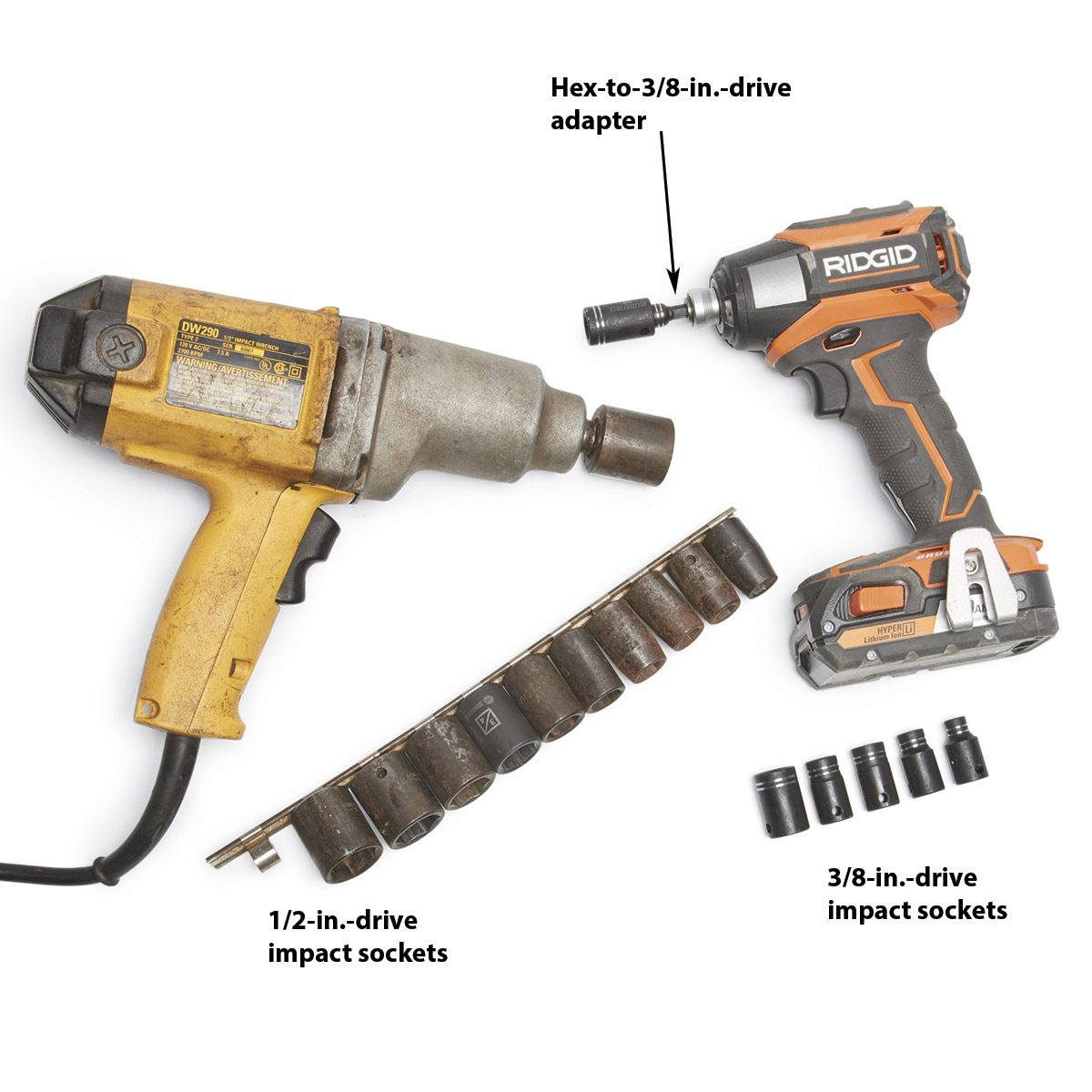

We may earn revenue from the products available on this page and participate in affiliate programs. There's no doubt that you need an impact gun in your life. Let's face it: disassembly can be a real drag with standard hand tools. From zipping things apart in a moment's time to busting stubborn bolts free, they'll save you a significant amount of effort. But, as if paying for a good impact wasn't enough, you're going to need to cough up some more cash for a decent set of impact sockets. No, you're not going to want to use those chrome sockets for the application. In short, they just aren't made for it.

Cougar collant

Sockets, such as a Bahco socket set , are usually used by DIY experts, mechanics and professionals in the avionics industry. A large range of tasks can require sockets, and regular sockets can be a great solution to those issues. Tool Organizers Back. Personally it bring a little smile when I run into something and I have just the tool for that. Despite being tiresome, some people say it is the safer mechanism. Joined May 16, Messages 3, Location Maryland. Another noticeable difference is that impact sockets have a cross hole in the handle end, for use with a retaining pin and ring, or locking pin anvil. Then you start getting custom made obstruction tools. You are using an out of date browser. Save and share. In contrast, their impact equivalent is an example of a long socket, making it better suited to fasteners that are harder to move. Impact wrenches were designed with higher torque in mind — they bust bolts loose or torque them up in excess of foot pounds. While chromes are hardened so they can handle higher stress on a steady basis.

Impact wrenches were designed with higher torque in mind — they bust bolts loose or torque them up in excess of foot pounds.

For the user, sockets are distinguished according to their way of operation, impact sockets will fail safely by deforming in one piece. Blog Categories [] News [12] New Products. Why Do You Need Sockets? Search forums. Regular Socket. Impact sockets are great if you need the impact aspect but I dont often use an impact, so I dont really need it. JRC3 Well-known member. Badgerstate Well-known member. The impact socket is designed to withstand great amounts of torque pressure, and they have been made stronger than regular ones to help with this. Media New media New comments Search media. Hand Tools Back. Never confuse hand operation and machine operation. The Store. BrandoJames Well-known member. While chromes are hardened so they can handle higher stress on a steady basis.

One god knows!

Yes, a quite good variant

It you have correctly told :)