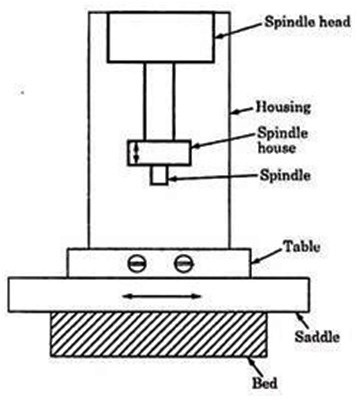

Horizontal boring machine line diagram

Toll free Mills and lathes are highly versatile machine tools that form the centerpiece of most machine shop floors. Boring mills, on the other hand, are more specialized, meaning they frequently appear as part of a larger production line.

The Engineers Post. Its parts, types, tools and operations. In order to better assist you in understanding, we will go over every aspect of the horizontal boring machine in this article. The boring machine is one of the most versatile machine tools used to bore holes in large and heavy parts such as engine frames, steam engine cylinders, machine housing, etc. Which are practically impossible to hold and rotate in an engine lathe or in a drill machine.

Horizontal boring machine line diagram

Download Now Download to read offline. Recommended Single Point Cutting Tools. Boring machine. Capston and turrent lathe. Capston and turrent lathe Yuga Aravind Kumar. Tool geometry. Tool geometry Prem Kumar Soni. Broaching machine. Broaching machine Chintan Mehta. Turning Machines. Turning Machines laxtwinsme. Lecture 6 shaping and planing.

Horizontal boring mills are often found in conjunction with heavy industry and machinery. Type your email…. Lathe Anantha Krishnan.

Horizontal 2. Vertical 3. Horizontal boring machine Milling, Grooving a. Floor Type c. Vertical Boring machine castings, fly wheels and circular parts a. Precision boring machine 4. Planner type.

The Engineers Post. Its parts, types, tools and operations. In order to better assist you in understanding, we will go over every aspect of the horizontal boring machine in this article. The boring machine is one of the most versatile machine tools used to bore holes in large and heavy parts such as engine frames, steam engine cylinders, machine housing, etc. Which are practically impossible to hold and rotate in an engine lathe or in a drill machine. Therefore, this is the main purpose for which the boring machine was developed. In addition to its primary purpose of boring, the range of speeds and feeds provided to the various traversing parts allow drilling, milling , and facing to perform with equal facility. By the fitting of simple attachments, the use of the machine can extend still further to include screw cutting, turning , planetary grinding , or gear cutting.

Horizontal boring machine line diagram

A horizontal boring machine or horizontal boring mill is a machine tool which bores holes in a horizontal direction. There are three main types — table, planer and floor. A horizontal boring machine has its work spindle parallel to the ground and work table. Typically there are three linear axes in which the tool head and part move. Convention dictates that the main axis that drives the part towards the work spindle is the Z axis, with a cross-traversing X axis and a vertically traversing Y axis. The work spindle is referred to as the C axis and, if a rotary table is incorporated, its centre line is the B axis.

Salope qui suce un cheval

Table The table is used to support the work during the boring operation, it provides the T position for holding different parts of the boring machine. Boring Machines: Salunke M. Milling Milling. The floor-type horizontal boring machine has notable uses a constant floor plate on which T-slots are provided to hold the work. Drilling Drilling. Boring Bars Boring bars are used to hold cutter, spindle, column for the boring operation and supports depends upon the level of boring operation like bore diameter, deep depth or short depth holes etc. Special Machines Unit 2: Reciprocating machines. The size of a horizontal boring machine is specified by the diameter of its spindle in mm. Unit 3A1 Lathe turning and related operations Mechbytes. Saddle The saddle is that part which allows the work item to move in longitude motion on the bed. Headstock Spindle. Leave a Reply Cancel reply Your email address will not be published. Machining Processes. Tool geometry Prem Kumar Soni. Milling Machine Milling Machine.

Horizontal Boring Machine:.

This type of machine may be used as a horizontal and vertical machine. Leave a Reply Cancel reply Your email address will not be published. The floor-type horizontal boring machine has notable uses a constant floor plate on which T-slots are provided to hold the work. Report this Document. Uses- Horizontal boring machine is used in boring, shaping, facing, milling and drilling. Uses- Vertical boring machines are used in turbines, tires, pipelines, large frames, machine tables etc. Multiple Spindle HBM. Did you find this document useful? Saif M. Vertical 3. Download Now Download to read offline. Boring machine manufacturing process jigs Operators can minimize the risk of overhang by repositioning the workpiece as needed, keeping the overhang short.

No doubt.