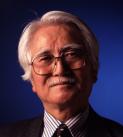

Father of kaizen

In Masaaki Imai founded the Cambridge Corporation, the international management consulting and executive recruiting firm.

He was He traveled the world teaching people about continuous improvement. Hear Mark read this post — subscribe to Lean Blog Audio. I had the fantastic opportunity to meet Mr. Imai a few times — once in Seattle when he was visiting and speaking at a healthcare organization, and twice during Japan study tours organized by Kaizen Institute.

Father of kaizen

Moreover, it means continuing improvement in personal life, home life, social life, and working life. The implementation of those 5 principles in any organization is fundamentally important for a successful Continuous Improvement culture and to mark a turning point in the progression of quality, productivity, and labor-management relations. Masaaki Imai is born in Tokyo, Japan. The first domestic automotive production is planned in Japan, and the Just-In-Time concept is observed. World War II to post-war economic reform period commences in Japan. Japanese companies gain strength in their quality and worldwide competitiveness. Imai works with Shoichiro Toyoda to observe the American way of business. Tools, such as Six Sigma, gain popularity though clouding the importance of a systematic approach. We noticed you're visiting from United States US. We've updated our prices to United States US dollar for your shopping convenience. Use Euro instead. Download PDF.

I'd like to first express my deepest condolences to Mr. Antiepileptics Document 3 pages.

Known as the father of Continuous Improvement CI , Masaaki Imai has been a pioneer and leader in spreading the kaizen philosophy all over the world. It was the first book to introduce the Lean philosophy to the world. His firsthand account is based on his close associations and travels with Shoichiro Toyoda and Taichi Ohno and reveals the secrets behind the success of Toyota and other Japanese companies. This book uses relevant case studies to detail 21 practical kaizen management practices, including methodologies and tools to apply where the real action occurs. The result: greater productivity, quality, and profits achieved with minimal cost and time. In keeping with his philosophy of never-ending Continuous Improvement , Mr.

He has consequently been recognized globally for the major influence and general acceptance of his groundbreaking work. On September 1, , Masaaki Imai celebrated his 90th birthday virtually with some of the global leadership team he worked with since he founded Kaizen Institute in The following day he was interviewed to reminisce on this milestone but also to gain some insights into his third book. The following are some highlights from this interview with a true sensei with two blogs to follow. As a young man in his late twenties, he was selected from thousands of applicants in Japan to represent Japan Productivity Centre in Washington D. There he hosted senior executives from his home country in their quest to learn from American businesses during their economic rebuild after WWII.

Father of kaizen

Toyota Motor Corporation emerged as a pioneer in implementing Kaizen, which sought to optimize production processes, eliminate waste, and enhance product quality. Several influential figures played pivotal roles in the development and dissemination of Kaizen principles. Beyond the automotive industry, Kaizen principles found application in areas such as healthcare, service, software development, and project management. At its core, Kaizen is driven by the belief that small, incremental changes lead to significant improvements over time. The philosophy emphasizes the involvement of all employees in the improvement process, fostering a culture of collective responsibility for continuous improvement. Key principles include respect for people, elimination of waste, continuous problem-solving, and an unwavering commitment to quality. Companies worldwide have adopted Kaizen principles to enhance efficiency, drive innovation, and empower their workforce.

Weather in longbridge

They offer broad consultancy, training, certification Kaizen College , and benchmarking services. Improvement begins with the admission that every organization has problems, which provide opportunities for change. Sectors of The Indian Economy Document 8 pages. Use Euro instead. You have entered an incorrect email address! Start your transformation journey. In , he established the Kaizen Institute to help Western companies adopt continuous improvement Kaizen practices. As presented by Imai ,Kaizen is an umbrella concept that embraces different continuous improvement activities on an organization as shown in Figure 1 9. Yes, email me about new posts, daily! It was an honor and a privilege to meet Mr. He traveled the world teaching people about continuous improvement.

Kaizen also applies to processes, such as purchasing and logistics , that cross organizational boundaries into the supply chain. By improving standardized programs and processes, kaizen aims to eliminate waste and redundancies lean manufacturing. Kaizen was first practiced in Japanese businesses after World War II , influenced in part by American business and quality-management teachers, and most notably as part of The Toyota Way.

Skip carousel. Kaizen Model Document 4 pages. Kaizen Document 3 pages. Definition and principles of Kaizen In the decade of , management techniques focusing on employee involvement, and empowerment through teamwork approach and interactive communications and on improving job design were not new, but Japanese companies seemed to implement such techniques much more effectively than others. Kaizen techniques became famous. He was Did you like this post? Kaizen generates processoriented thinking, is people-oriented, and is directed at people's efforts. Trash Document 1 page. Table 2. We work directly with our clients to create processes that highlight problems while simultaneously training and empowering their teams to solve them. The book was an immediate global success because of which the Kaizen concept was introduced internationally from Japan at corporate and management level. Known as the father of Continuous Improvement CI , Masaaki Imai has been a pioneer and leader in spreading the kaizen philosophy all over the world. The result: greater productivity, quality, and profits achieved with minimal cost and time.

I join. And I have faced it.

And how in that case it is necessary to act?

Do not take in a head!