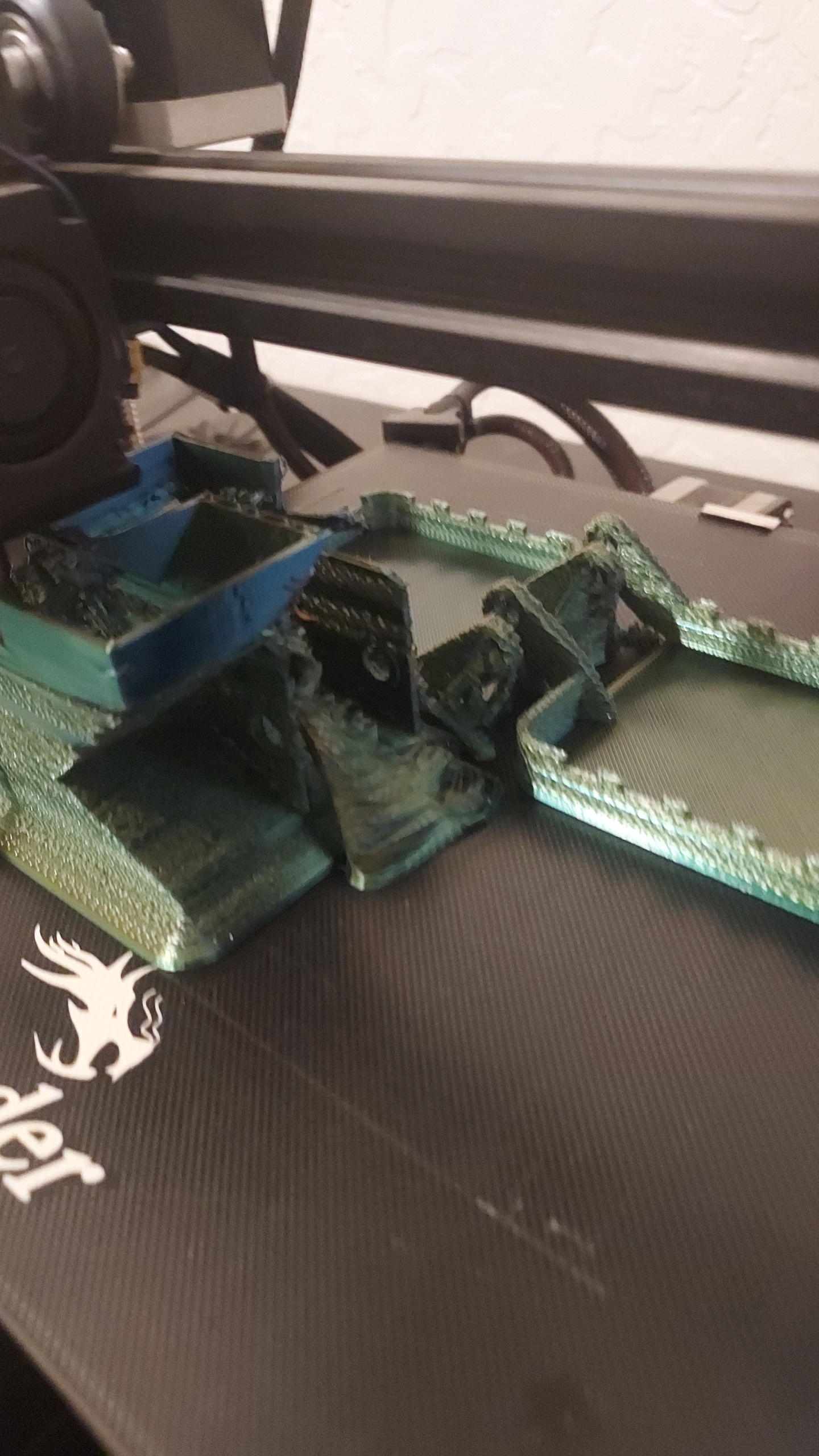

Ender 3 not extruding

The Ender 3 Pro extruder not feeding filament when printing is one of the worst experiences for 3D printing enthusiasts. The culprit is easy to identify, and the problem can be easier and quicker to fix than you think.

If your printer was extruding properly at the beginning of your print, but suddenly stopped extruding later on, there are typically only a few things that could have caused this problem. We will explain each common cause below and provide suggestions for fixing the issue. If your printer was having trouble extruding at the very beginning of the print, please see the Not Extruding at Start of Print section. This one is pretty obvious, but before checking the other issues, first verify that you still have filament leading into the nozzle. If the spool has run out, you will need to load a new spool before continuing the print.

Ender 3 not extruding

This guide covers the frequently reported complaints of Creality Ender 3 users and lists the most effective solutions for each problem. The Creality Ender 3 is a fan-favorite 3D printer that retails far below the expected price for printers of this caliber. Owing to its low price and higher end features, a lot of beginner hobbyists buy the Ender 3 as their first 3D printer. Under-extrusion is by far the most common problem faced by Ender 3 users. You can identify an under-extrusion problem by evaluating your test prints. Flow rate is an essential aspect of print quality that is easy to overlook when tuning settings for a new filament or when setting up a new printer. Decreasing the print speed will ensure that the filament is laid evenly and has sufficient time to set before the next portion of the print is deposited on the build surface. Have a quick test print ready because you will likely have to print a few until you find the optimal settings for your printer. Adjusting the Z-distance, which is the vertical distance from the nozzle to the print bed, can typically improve layer uniformity and setting. You can typically identify a poor Z-distance setting by a thin first layer. If you are still having problems, follow our more comprehensive bed leveling guide to cover any nozzle or bed alignment issue that could be affecting your print quality. Though this is unlikely to be an issue for brand-new machines, if you have used your Ender 3 printer several times without problems and are suddenly facing extrusion problems, it is very likely that a clogged nozzle is to blame. Run a short test print and carefully watch the filament as it is extruded. If it begins to curl as it comes out, there is a partial clog in the nozzle.

Grinding Filament. If you buy a cheaper part, it might wear out faster or present feeding problems right from the start. There are a few fixes for this problem, but the easiest are careful re-assembly and adding a shim to the Z-axis stepper.

This issue is a very common one for new 3D printer owners, but thankfully, it is also very easy to resolve! If your extruder is not extruding plastic at the beginning of your print, there are four possible causes. We will walk through each one below and explain what settings can be used to solve the problem. Most extruders have a bad habit of leaking plastic when they are sitting idle at a high temperature. The hot plastic inside the nozzle tends to ooze out of the tip, which creates a void inside the nozzle where the plastic has drained out. This idle oozing can occur at the beginning of a print when you are first preheating your extruder, and also at the end of the print while the extruder is slowly cooling.

While it all seems so simple when it comes together, extrusion is a pretty complex operation that relies on all the distinct software and hardware components working correctly together, which causes it to have multiple points of failure where even one of the parts becoming inoperational can bring everything to a halt. To obtain the official firmware file that Creality ships for your particular model of Ender 3, you can visit the support section on the official Creality webpage , where you will be able to select different firmware files based on factors such as mainboard version and whether a BLTouch sensor is attached to your Ender 3. In the case where there indeed are heating issues, which would practically make it impossible for your Ender 3 to extrude filament even if everything else is working as intended, the first order of business, as you may predict, is resolving this problem to restore the heating capabilities of the hotend, and see whether the extrusion issue continues afterward. For this process, our primary recommendation would be to ensure that the heater cartridge wires are connected correctly to the mainboard without any looseness or wiggle that could lead to the connection becoming compromised by disconnecting and re-connecting them carefully, as such disconnection can easily prevent the heater cartridge from operating as intended and cause the hotend not to heat up. While the more advanced users may be able to go down the route of testing the power supply voltage with a multimeter to find out whether the power supply is in good shape or not, which would point them toward the problematic component without having to replace both, the fact that this may not be an option for everyone makes replacing the components or sending your 3D printer in for a repair the go-to solution in most cases. A clogged nozzle is perhaps the most common problem that can prevent your Ender 3 from extruding filament as it should, as there are many distinct factors that can lead to the nozzle eventually becoming fully clogged and leaving no room for the filament to pass anymore. In the case where it becomes impossible to move the filament through at all, or nothing comes out of the nozzle even when you have managed to push some filament in, we can say that the nozzle of your Ender 3 is indeed clogged, as it should be possible to get the filament through the nozzle manually without issues provided that the hotend is at the correct temperature for the filament to melt. Next, grab the needle that ships with your Ender 3 for this exact purpose of unclogging the nozzle, place it inside the nozzle, keep pushing and pulling the needle to break down any clumps that may be obstructing the path of the filament, pull the needle out to clean any residue that may gather on it, and repeat this process a few times until the needle comes out clean.

Ender 3 not extruding

If your 3D printer does not deposit enough filament during printing, it might have under-extrusion issues. When the printer is supposed to extrude a specific amount of filament, it falls short of that amount, resulting in various issues with your print quality, like poor layer adhesion, stringing and oozing, and even imperfections in the surfaces. Under-extrusion can result from many factors, and you need to take your time to know the root cause and fix it. Below we highlighted the different ways you can use to fix under-extrusion problems. Start by checking the nozzle for any blockages and clean it. You can use a sharp needle or wire to see if it will unclog the nozzle.

Detroit massage forum

Use a pair of scissors to cut the filament tip at a degree angle. A computer power supply found in most electronics stores works, but specialized Ender 3 supply options are available in stores. Clean the print surface Use rubbing alcohol and a microfiber cloth to remove any debris, dried filament, and dust from the build surface. A clogged nozzle is perhaps the most common problem that can prevent your Ender 3 from extruding filament as it should, as there are many distinct factors that can lead to the nozzle eventually becoming fully clogged and leaving no room for the filament to pass anymore. Next on our list of things that can prevent your Ender 3 from extruding filament is the extruder tension, which determines how tightly the extruder gear grips the filament, being misconfigured, as such a misconfiguration can lead to a scenario where the extruder becomes unable to move the filament even with the motor working without any issues. To solve this problem, the first step we recommend is to loosen the extruder tension all the way down as a starting point with the hex key that comes with your Ender 3 since this will make it easier to perform the necessary adjustments. Decreasing the print speed will ensure that the filament is laid evenly and has sufficient time to set before the next portion of the print is deposited on the build surface. The next thing you will want to check is your extruder nozzle. On the other hand, in a scenario where the extruder gear ends up spinning with this setup, our recommendation would be to run more tests by mixing and matching the two separate wires, stepper motors, and stepper drivers such as connecting the extruder motor to the Z-axis driver with the original wire first to see if it still works, and if it does, connecting the Z-axis motor to the E-axis driver to confirm that the problem indeed resides with the E-axis driver , which should practically lead you to the component the wire or the mainboard that requires replacing. Owing to its low price and higher end features, a lot of beginner hobbyists buy the Ender 3 as their first 3D printer. One tried-and-true solution to this hot end problem is this hot end fix , which adds a spacer inside the hot end that allows the tubing to be compressed tightly against the nozzle and minimizes the gap that can occur in some stock Ender 3 printers. If none of the above causes apply to you, then it is very likely that the extruder is clogged. If your printer was extruding properly at the beginning of your print, but suddenly stopped extruding later on, there are typically only a few things that could have caused this problem.

The most common cause of these defects is under extrusion. While Creality developed one of the most versatile and budget-friendly 3D printers , the Ender 3 still has its fair share of issues.

Clean the extruder and remove any clogs if needed. For example, if you enter a value of 0. Look at the printer and see what happens after you hit the start button. Bed adhesion problems are easy to spot—if your first layer is curling up or not setting properly on the build surface, you likely have adhesion problems that can affect the quality of the entire print. If the extruder gear is not turning as your Ender 3 is running the extrusion command, this would effectively mean that there is an issue that stops the extruder stepper motor from operating as intended, which would explain why your Ender 3 is unable to extrude filament. This is particularly helpful for larger prints. Afterward, get the extruder motor to rotate by either extruding some filament through either the LCD controller a higher value is better as it will cause the motor to spin longer and give you more time to observe the situation or running the G1 E G-code command from a G-code terminal. However, if you cannot see through it, then use a Q-Tip with some Isopropyl Alcohol on it and swab out any clogs or deposits that may have built up on the inside of your nozzle. The filament has stripped against the drive gear. Larger prints, however, are much more likely to have significant temperature differences that affect print quality and stability. Common Solutions.

I have thought and have removed this question

I like your idea. I suggest to take out for the general discussion.