Electrical pull box sizing

Chapman Electric Supply, Inc.

Until now, the easiest way to transport electricity from a power source to any equipment throughout a structure is through electrical wires. Connecting various devices like lighting fixtures and outlets to the power source means lots of cables to manage. Since we don't want our cables lying around the floor or within the walls and ceiling, we use conduits like tubings and pipes to keep the wires together organized. We then connect these conduits using connectors and boxes where we can reorganize the wires to direct them to the locations they need to be. We call these boxes our junction boxes or pull boxes as we pull wires to them before inserting them back into other conduits.

Electrical pull box sizing

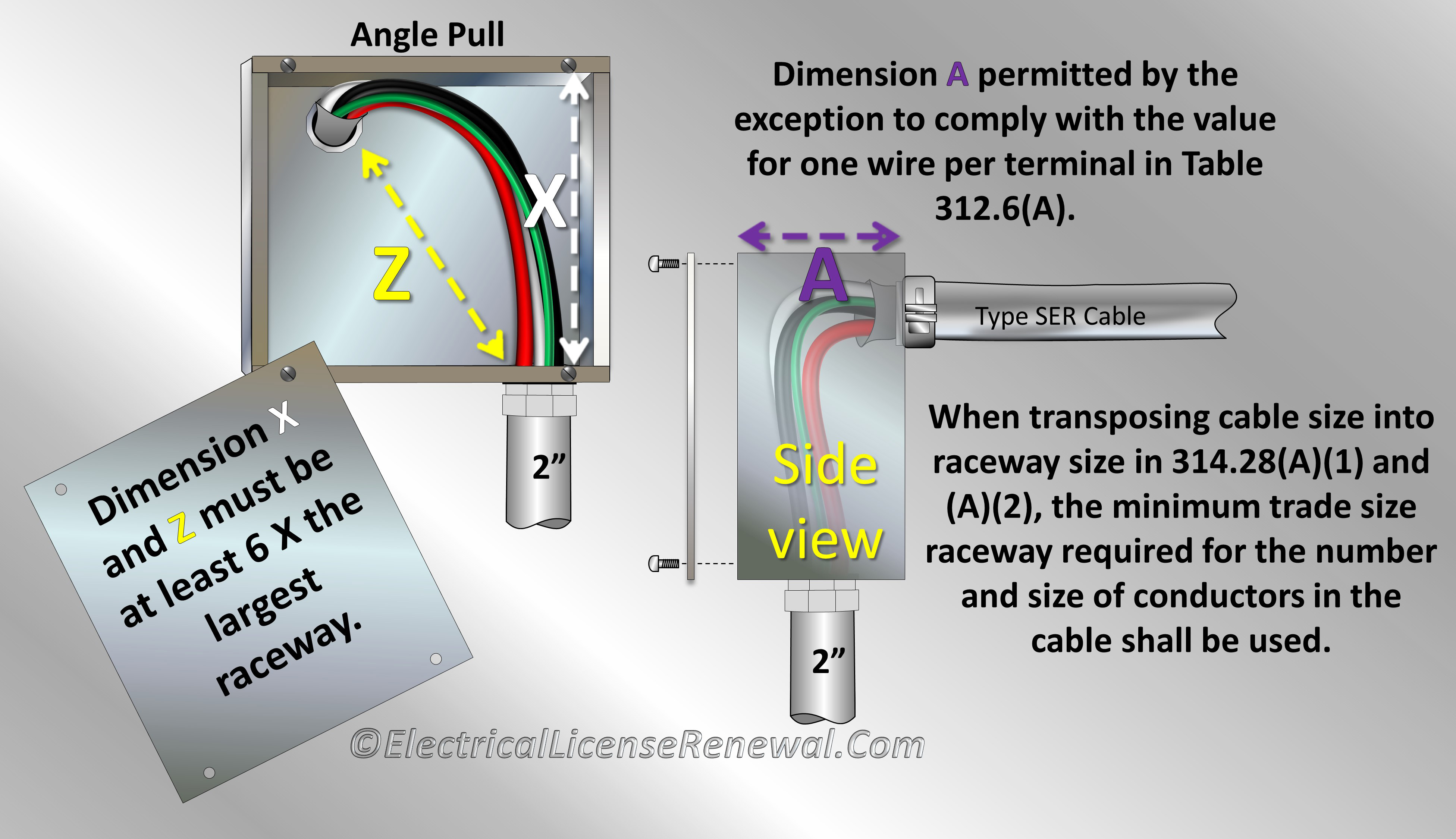

Pull boxes are used along with conduit to simplify wiring installation , hence their name. They are made of sheet metal , cast metal, or a non-metallic material, and provide a way to pull conductors long distances without placing excessive strain on the wire or insulation. Pull boxes allow long wiring runs to be installed in shorter intervals, and can be used for both straight and angled pulls. Although they have the same appearance as junction boxes, pull boxes do not have wiring connections inside. They are only access points for pulling and feeding conductors into a raceway system. Their use is mandatory in conduit runs where the number of bends between outlets exceeds the maximum number permitted by the NEC National Electric Code. Pull box sizing is based on the size and number of conductors, as well as the number of raceways and their diameter. This post will provide an overview of the sizing rules for the most common types of pulls, along with a calculation example. In straight pulls, conduit enters and leaves on opposite sides of the box. The depth of a box for a straight pull is determined by the size of the largest conduit and by space required by locknuts and bushings. On the other hand, the pull box length must be at least eight times the diameter of the largest conduit:. Boxes and conduit bodies containing conductors 4 AWG or larger, and containing angle or U-pulls must be sized in accordance with the specifications of NEC article For angle pulls, the distance between each raceway entry inside the box and the opposite wall of the box must be the sum of the following:. The calculation procedure would be as follows:. In addition, the straight distance between the entry and exit points of each circuit must be six times the respective conduit diameter.

ActionDave Chief Moderator Staff member. After that, electrical pull box sizing, you can now follow these steps when using our junction box or pull box sizing calculator: Select the size of the largest conduit attached to the junction box where you will pull wires straight horizontally.

Forums New posts Search forums. What's new New posts. Log in Register. Search titles only. Search Advanced search…. New posts.

Hello there, fellow readers! Have you ever heard of a pull box? If not, then this article is just for you! It is a device that has been used in electrical systems for decades, yet not many people know about it. In this article, we will give you a comprehensive guide to pull boxes, including their functions, types, and installation. A pull box is an electrical device that is used in electrical systems to provide a junction point to splice and connect wires. It is also referred to as a handhole or a splice box. The primary purpose of a pull box is to enable easy pulling of electrical wires from one point to another. It is also used to provide insulation and protection to the wires, as well as to facilitate easy maintenance of the electrical system.

Electrical pull box sizing

Pull boxes are used along with conduit to simplify wiring installation , hence their name. They are made of sheet metal , cast metal, or a non-metallic material, and provide a way to pull conductors long distances without placing excessive strain on the wire or insulation. Pull boxes allow long wiring runs to be installed in shorter intervals, and can be used for both straight and angled pulls. Although they have the same appearance as junction boxes, pull boxes do not have wiring connections inside. They are only access points for pulling and feeding conductors into a raceway system. Their use is mandatory in conduit runs where the number of bends between outlets exceeds the maximum number permitted by the NEC National Electric Code. Pull box sizing is based on the size and number of conductors, as well as the number of raceways and their diameter. This post will provide an overview of the sizing rules for the most common types of pulls, along with a calculation example. In straight pulls, conduit enters and leaves on opposite sides of the box.

Av4.us

In addition, the straight distance between the entry and exit points of each circuit must be six times the respective conduit diameter. Books vs e-books Discover the ultimate paper books vs. In the next section of this text, we will discuss the minimum requirements when choosing the proper junction box sizes. Going off of memory but it should be six times the diameter of your largest conduit plus the diameter of each additional conduit. Location Illinois Occupation retired electrician. The sum of diameters for all other raceways on the same wall and row. Forums New posts Search forums. I'm looking for the minimum size allowable for the pull box. This will hall under the angle-pull rules. Log in. Repeat steps 3 to 6 , but this time, for the angle pulls from the right, top, and bottom sides of your junction box, if applicable. The depth of a box for a straight pull is determined by the size of the largest conduit and by space required by locknuts and bushings.

In-stock distribution boxes, general in sizes, flexible in use, eligible to protection categories. Made-to-measure distribution boxes in a variety of materials, types and ratings. Mounting plates, locks, racks, cables, brackets…everything to empower your enclosure system.

It weighs about five times as much as the other one! Importance of the Design Procedure While pull boxes are convenient, keep in mind that they require materials and labor, and can increase project cost if used excessively. So you have a 2'' straight pull and a 3'' angle pull. Straight Pulls In straight pulls, conduit enters and leaves on opposite sides of the box. Energy efficiency also helps optimize electrical installation costs. I took a pic of the outside today, after we ran the 4" conduit inside. Pull boxes are used along with conduit to simplify wiring installation , hence their name. Our junction box calculator can handle up to 10 additional conduits per row. Option 1 is 8 times the diameter for the straight pull, and Option 2 is 6 times the largest raceway plus all other diameters. Since you are using smaller conductors than you would normally see in 4", the LBs may be large enough, but you will have to do a calculation as conduit bodies that are marked are marked for "3 size XX conductors" so any time you have more than 3 conductors you have to do the calculations found in the last sentence of U-Pulls When conductors enter and leave from the same wall, the distance from where the raceways enter to the opposite wall is calculated with the same procedure used for angle turns: Six times the trade size of the largest raceway in a row. But, with only a 3" on the side wall for now , is the 18" adequate? Select None if there aren't any. These calculations also start with the largest raceway size, but then get a little more complicated.

0 thoughts on “Electrical pull box sizing”