Dupont 22 elements of safety

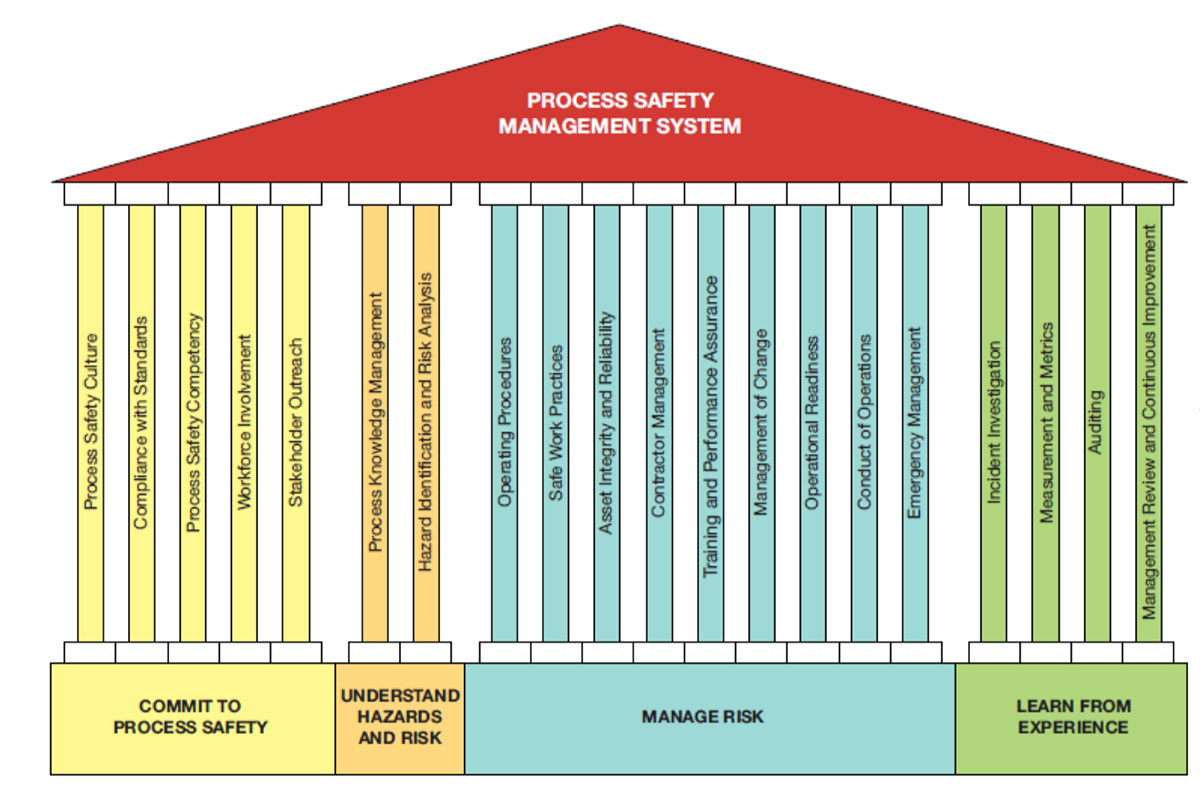

Process safety management system. Process safety management system 1 of Download Now Download to read offline.

Operating on the Edge Achieving a competitive edge requires a system that drives continuous improvement and protects people, the environment and your business. Fit for the Edge If your business is working with hazardous materials or mechanical operations, in remote locations or in extreme environments, youre working on the edge. Guarding against that one-in-a-million chance of a major industrial trauma is as important to your workplace as its everyday safety activities. Organisations that have experienced few or no severe incidents may be relying on their good fortune rather than an alert safety culture and operating discipline. Others, making improvements to business structures and processes may be in danger of overlooking the need to manage both the inherent and unforseen risks. Whether your business is a higher or lower hazard operation, working with the DuPont team to improve your PSM strengthens your organisations confidence in its physical condition, risk awareness and incident preparedness. Gaining a reputation for operational and safety excellence, driving for greater performance and becoming an employer of choice will see your business achieving that competitive edge.

Dupont 22 elements of safety

Advance our EHS culture by focusing on leading causes of injuries, changing mindsets and behaviors, and reducing exposure to high risk activities. Improve our systems and execution on alarm management process control, human factors, and effective operating procedures to reduce Tier 1 and 2 incidents. At DuPont, we re-commit ourselves to our core value of health and safety every single day. This commitment is embodied in our company culture, our stakeholder engagement, and in the innovations we produce for the world. In healthcare, for example, our unique portfolio offers increased efficiencies, improved formulations, and cost savings in the development of new medicines, ultimately helping patients live healthier and more comfortable lives. Our non-irritating soft skin adhesives, when incorporated into wearable pharmaceuticals, could offer a more effective and reliable alternative to conventional vaccine and medicine delivery methods. Our Environmental, Health and Safety EHS Management Systems, which cover both employees and contractors, ensures that we continually prioritize our commitment to health and safety. The system provides us with a process to identify and evaluate hazards and risks associated with our product development and manufacturing processes, distribution, and other operations. We then establish goals and objectives to address any significant hazards and risks, taking the feedback and concerns of employees, contactors, communities, customers, suppliers, and other stakeholders into consideration. Creating an effective workplace safety strategy begins with accountability, root cause analysis and performance reviews.

DuPont Process Safety Management Operating on the Edge Achieving a competitive edge requires a system that drives continuous improvement and protects people, the environment and your business.

.

DuPont tests a new safety approach that goes beyond traditional behavioral-safety programs. Instead of taking a sprawling corner office when he joined the company, former Alcoa Inc. Instead, he made safety his top priority and mission, saying that in order to be considered a world-class company; it first had to become the safest. His goal was to see that no employee was injured in the workplace. Companies like Alcoa are no longer making safety a priority, but a value. Many of these same companies already have in place robust safety procedures and practices and have industry leading performances to match. That said, a growing number are looking for the next opportunity to move beyond plateaued safety performance, which for many is at or below a total injury recordable rate of 1. Since the s, this plant has been producing Nomex , a flame-resistant meta-aramid fiber that is employed as a dielectric insulator for high temperatures.

Dupont 22 elements of safety

Advance our EHS culture by focusing on leading causes of injuries, changing mindsets and behaviors, and reducing exposure to high risk activities. Improve our systems and execution on alarm management process control, human factors, and effective operating procedures to reduce Tier 1 and 2 incidents. At DuPont, we re-commit ourselves to our core value of health and safety every single day. This commitment is embodied in our company culture, our stakeholder engagement, and in the innovations we produce for the world. In healthcare, for example, our unique portfolio offers increased efficiencies, improved formulations, and cost savings in the development of new medicines, ultimately helping patients live healthier and more comfortable lives. Our non-irritating soft skin adhesives, when incorporated into wearable pharmaceuticals, could offer a more effective and reliable alternative to conventional vaccine and medicine delivery methods. Our Environmental, Health and Safety EHS Management Systems, which cover both employees and contractors, ensures that we continually prioritize our commitment to health and safety. The system provides us with a process to identify and evaluate hazards and risks associated with our product development and manufacturing processes, distribution, and other operations. We then establish goals and objectives to address any significant hazards and risks, taking the feedback and concerns of employees, contactors, communities, customers, suppliers, and other stakeholders into consideration. Creating an effective workplace safety strategy begins with accountability, root cause analysis and performance reviews.

White duck paint colour

The DuPont Approach DuPont PSM involves the integration of three broad dimensions: Facilities to manufacture and handle hazardous materials Technology of the process Personnel who operate, maintain, and support the process. Providing Management Leadership and Commitment 3. Implement holistic water strategies across all facilities, prioritizing manufacturing plants and communities in high-risk watersheds; and enable millions of people access to clean water through leadership in advancing water technology and enacting strategic partnerships. Tap the capabilities of all employees. Lean organization. Personal Growth Documents. About Us. EHS Presentation. Critical risk information, as well as technology and process descriptions are not only the basis for risk analysis, but could be the critical blueprint to disaster recovery. Protecting workers around the world.

.

Apply environmental principles and advocate conservation. For a business to grow and prosper its processes and technology must be reviewed periodically to ensure optimal performance. Process Safety Kpi ArthurGroot. Whether your business is a higher or lower hazard operation, working with the DuPont team to improve your PSM strengthens your organisations confidence in its physical condition, risk awareness and incident preparedness. Download now. Hse nitish Nitish Sharma. The objective of a DuPont PSM engagement is to assist your business in identifying areas of strength and opportunities for development, to keep you fit for the edge. All deficiencies must be corrected promptly. Guarding against that one-in-a-million chance of a major industrial trauma is as important to your workplace as its everyday safety activities. Honeywell Inc an overview Musthafa K M. Process: how the element is supported through procedure. Presentation hazop introduction. Recently uploaded Plastic pollution and it's impact on marine ecosystems.

You are absolutely right. In it something is and it is excellent idea. It is ready to support you.