Diamond power soot blowers

Insist on the original! Using superheated steam, saturated steam, compressed air or water, our sootblowers are trusted to remove deposits, prevent plugging of gas passes and maintain boiler efficiency.

Industrial Boilers America is a leading soot blower manufacturer providing premium grade Diamond Power soot blowers and replacement parts. We offer a variety of premium-grade industrial soot blowers that meet the needs of your application and are designed to reduce the cost of thermal heat loss and maintenance. Our product is more superior and it will also save you money on the overall cost. Our team of engineers can provide the exact replacement or even design the right industrial soot blower or soot blowing system for your application at a competitive price and delivery. We work with our customers to find the design that works best for their application with an aim to provide cost savings that helps our customers get a quicker return on their investment. When you want to grow, we will show the way. The steel is thicker, the material is thicker, and everything lasts longer.

Diamond power soot blowers

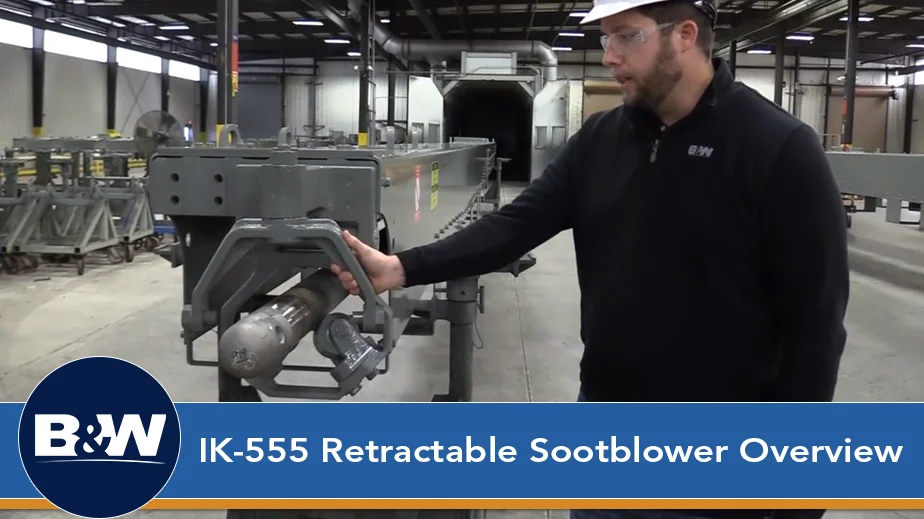

A sootblower is a device for removing the soot that is deposited on the internal furnace tubes of a boiler during combustion to prevent plugging of the gas passes and maintain boiler efficiency. Steam is normally used as a medium for blowing away the soot since capital cost of steam pressure reducing equipment and drain is less than the cost of compressors, motors and control of air systems. Water is also common for furnace cleaning. We can help you find cleaner energy solutions for a changing world. Products search. Most common types of sootblowers: Furnace wall sootblower IR Insertable Rotating for cleaning the wall on which it is attached Long retractable sootblower IK Insertable Kinetic for cleaning the convection pass Generating bank and economiser sootblower G9B for fully inserted rotating element Rake sootblower for cleaning economiser and finned tubes Air heater sootblower for rotating assemblies Steam is normally used as a medium for blowing away the soot since capital cost of steam pressure reducing equipment and drain is less than the cost of compressors, motors and control of air systems. View Cart. Please wait while you are redirected to the right page

Working with us means lower costs, which allows you to reinvest in yourself and expand your impact on the planet. Our specialized designs and configurations meet customer needs for sootblower precision, reliability and efficiency.

Insist on the original! With more than a century of experience in boiler cleaning, you can depend on low maintenance, reliability, versatility and maximum cleaning performance backed by experience. And, we provide the advanced camera technology to bring firing conditions visible in demanding environment. Customers benefit from our ability to provide service programs and allow our forward-looking clients to concentrate on their core businesses. Further, our diagnostics, controls and ongoing service are unparalleled in the industry.

Every combustion engine that heats a boiler creates soot of some kind, regardless of its fuel source. Soot blowers remove the sooty remnants of combustion from furnace and boiler tubes, reducing the risk of fire and increasing the efficiency of the engine. Diamond Power Soot Blowers represent the top of the line for soot removal operations. Many industries around the world use boilers to generate power for their production and manufacturing needs. The fuels used to heat boilers vary, however, depending on the location of the plant and the energy regulations that govern that region. For these reasons, many companies use soot blowers to remove soot from their machine and engine pipes and ducts. Soot blowers use air or steam to clean away the soot from inside pipes and furnaces.

Diamond power soot blowers

Industrial Boilers America is a leading soot blower manufacturer providing premium grade Diamond Power soot blowers and replacement parts. We offer a variety of premium-grade industrial soot blowers that meet the needs of your application and are designed to reduce the cost of thermal heat loss and maintenance. Our product is more superior and it will also save you money on the overall cost. Our team of engineers can provide the exact replacement or even design the right industrial soot blower or soot blowing system for your application at a competitive price and delivery. We work with our customers to find the design that works best for their application with an aim to provide cost savings that helps our customers get a quicker return on their investment. When you want to grow, we will show the way. The steel is thicker, the material is thicker, and everything lasts longer. We are focused on relationships over profit.

Fast pace brownsville tennessee

It controls thermal impact while cleaning previously hard-to-reach surfaces. High Quality. Renewable Overview. The LRSB starts at the beginning of the industrial boiler and slowly moves through it, rotating degrees to remove soot from all surfaces. A fixed rotary soot blower is attached to the industrial boiler and unlike the other soot blowers, this does not retract like the others listed above. We have cooperated for a long time. Improves operational efficiency Industrial Boilers last longer Keeps boiler running smoothly, safely, and efficiently Reduces the cost of thermal heat loss Reduces the need for maintenance. DPSC begins producing reliable, direct-reading water level gauges. A wall soot blower is a small piece of industrial equipment that connects to the outside of the industrial boiler. A long retractable LRSB soot blower is an industrial device that extends a long nozzle into the industrial boiler. Our product is more superior and it will also save you money on the overall cost. This moisture ends up mixing with soot and other byproducts, which creates a fine-grain deposit.

Insist on the original!

High Quality. As you run your industrial boiler, the combustion produces byproducts like soot, which is a form of carbon. A long retractable LRSB soot blower is an industrial device that extends a long nozzle into the industrial boiler. Precisely designed nozzle head and rugged sootblower structure guarantees the positive cleaning without damaging the materials of the heat exchanger. Blowing radius m. The IK's single rack and pinion design offers an economical alternative for those seeking performance and durability. General Terms and Conditions German. Convection Pass. A German immigrant named Raphael Herman establishes a company in Detroit for the manufacture of hand-operated boiler cleaning devices. Air Heater Soot Blowers Air heater soot blowers are specifically designed to clean the air heaters of your industrial boiler.

I apologise, but, in my opinion, you commit an error. I can defend the position. Write to me in PM, we will communicate.

I apologise, but, in my opinion, you are not right. I am assured. Let's discuss it.