Cummins top stop injector adjustment

Pro-football-reference Soldiers now has a few new forums, read more about it at: New Munitions Forums! Sure, ad-blocking software does a great job at blocking ads, but it also blocks useful features of our website like our supporting vendors.

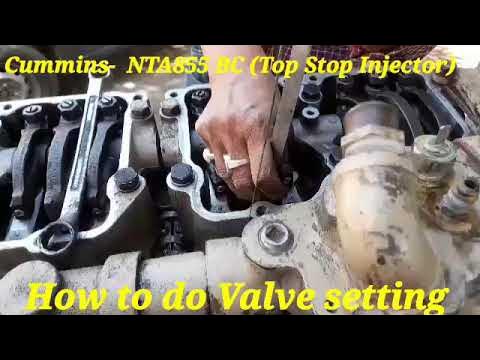

We'll discuss the theory and procedures for setting injector plunger travel using the dial indicator method D. Included is the recommended procedure for checking and adjusting crossheads. We'll discuss the effects of crosshead adjustment related to valve operation. This is a Top Stop adjustment fixture It's required to set Top Stop plunger travel, and to torque the splined locknut to 55 ft. The plunger travel is set by preloading the injector spring with the weighted handle at a prescribed travel.

Cummins top stop injector adjustment

Log in. Sign up. Home Forums Farming Community Tractors. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. Can you use either one? Mine is a big cam 1. It appears that there are several different injectors that are used by Cummins How do you verify which you have I have adjusted valves for years but there methods seem a little vague I don't want to have to do it 5 times to get it right and I do not want to break anything. Cummins was not very helpful because they are not computerized controls most of the older guys that did the old stuff arn't around anymore. Sort by Oldest first Oldest first Newest first Most reactions. I don't want to bend or break anything, and I am not saying you would have me do anything to damage anything, I am just trying to understand the process through the mechanics of how it is done. The inner base methods either using a dial indicator for std injectors or the inch pound setting for top stops doesn't ensure the injector is seated when at top dead center. Keep in mind just because the data tag shows an injector trave spec ex. You can tell if you have top stops if there is a spring holder holding the spring inside the injector.

When the gauge is moved you should feel a slight drag. If I find some better directions I'll post them, or maybe some one has an early 's manual handy.

Log in. Sign up. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. Sort by Oldest first Oldest first Newest first Most reactions.

This post is mainly written to introduce how to adjust crosshead, injector and valves of Cummins NT diesel engines correctly. Pay attention to reading and you will learn more. Crosshead Adjustment. Note: Crosshead adjustment should always be made before attempting to adjust the valves. Loosen the locknut on the crosshead adjusting screw. Turn the adjusting screw out at least one turn. Hold the crosshead down against its mating valve stem. Turn the adjusting screw back in until it touches the valve stem. Hold the adjusting screw in this position and tighten the locknut. Check the clearance between the crosshead and valve spring retainer 1 and 2.

Cummins top stop injector adjustment

Follow along with the video below to see how to install our site as a web app on your home screen. Note: This feature may not be available in some browsers. Forums New posts. What's new New posts Latest activity. Log in Register. What's new. New posts.

How to import music from itunes to iphone

If positioned past the adjustment point, the intake valves will start to open, causing loose clearance settings. It appears that there are several different injectors that are used by Cummins How do you verify which you have I have adjusted valves for years but there methods seem a little vague I don't want to have to do it 5 times to get it right and I do not want to break anything. Depends on which method you used, inner base, or outer base. Report this Document. They have just passed bottom-dead-center beginning their upward strokes. Remember, always check overhead settings at the recommended scheduled maintenance intervals for optimum engine life. To help reduce wear and power consumption. Don't ever try setting top stop injectors using the travel method. Use this check to identify the closed valves. It turns out that each injector is about two turns of the screw too tight and needed to be backed off these two turns. Top Stop injectors are easily identified by the splined locknut on top of the injector body. About '73 Cummins came up with the NTA engines.

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

So, any takers to verify that I finally got it right? Insert Quotes Quotes Post Reply. One gasket choice has to provide a satisfactory average for two cylinders. Their ads help keep Steel Soldiers going. Report this Document. JavaScript is disabled. Autocar UK - 13 November This valve lift graph shows the relationship between cam lobe positioning and crank stroke. I think I described adjustment in the write up I did. Appxxxxxxxxxxxx Appxxxxxxxxxxxx. Come join the discussion about specifications, accessories, troubleshooting, maintenance, and more! Explore Our Forums. The exhaust lobe is nearing T. We welcome you to register using the "Register" icon at the top of the page. Once again by referencing our valve and injector adjustment table, we know to check for loose rocker levers on 5 and 2.

0 thoughts on “Cummins top stop injector adjustment”