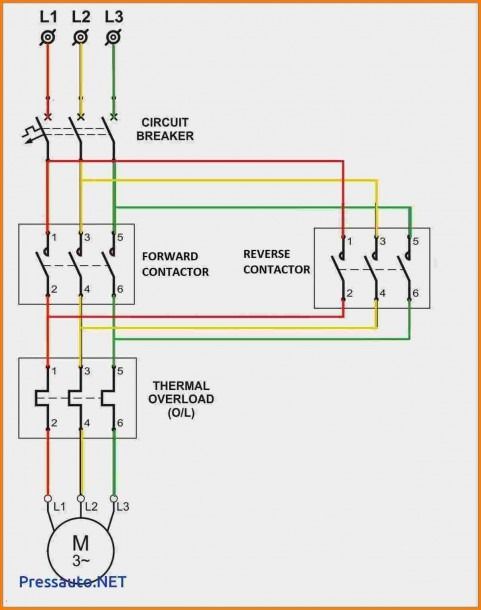

Contactor wiring diagram

Last Updated: February 8, This article was co-authored by Ricardo Mitchell.

This diagram shows how to make Timer and contactor wiring diagram. First, we need to connect the TP MCB with the power source, then connect the MCB with the contactor, then connect the timer with the magnetic contactor. Now this circuit is ready for use. I may make a commission if you buy the components through these links. I would appreciate your support in this way! Read Also: 3 phase transformer wiring 3 phase motor contactor diagram Change Over With Electric Motor wiring 3 phase contactor wiring diagram Timer contactor wiring diagram Advertisements.

Contactor wiring diagram

View Cart. The wiring diagram is basically the same for all of them, but you have to make sure you supply the right voltage type for the coil you are using. Above is the standard wiring method. There are some advantages and disadvantages with this wiring method. If you need to have a HOT wire when the unit is off unlikely , then this will be the method you use. This is called the "normally off" setting, and it will only carry 3 amps when the unit is off, but on the other leg, 30 amps at v or v when the unit is off. This can be handy, but it means you have legs that are always hot and are a shock concern if you touch the unit when it is off. This is the wiring we used for tanning beds and our own UV curing rigs. You are moving the power in and removing the ability to have a "normally off" power setting, but that also removes the shock hazard. This will carry 30 amps, and is the wiring diagram that most of you will use. This relates only to the COIL itself, not what the relay will handle. When configuring the 0 and 1 poles, polarity doesn't matter. For V operation most common , just connect a neutral wire to either 0 or 1, then you should have some kind of a switch that sends a hot line to the other pole. A standard home grade light switch is perfect for this, mounted in a standard box.

In the context of a timer switch, the load wire connects to the electrical load, such as a light or an appliance, that the switch is intended to control. That way, when the switch is on, you are sending power to the relay, causing it to turn on, contactor wiring diagram.

.

Knowing how to wire an electrical contactor in industrial and commercial applications is an important step for managing electric motor operation. This post reviews electrical contactor wiring, how electric contactors work, and introduces standard electrical contactor wiring diagram instructions to help you when selecting and installing Contact Kits and Motor Control Parts. An electric motor contactor is an electromagnetic switch used to control the flow of power to an electric motor. As a motor control accessory , It includes a coil, which is usually connected to a low-voltage control circuit, and a set of contacts, which regulate the high-voltage power circuit to the motor. When a voltage is applied to the coil, an electromagnetic field is created, which attracts a movable armature. This movement shuts the contacts, allowing current to flow from the power supply to start the motor. When the coil is de-energized, the contacts open, shutting down the motor.

Contactor wiring diagram

Siemens contactors are widely used for switching and controlling electrical loads, making them essential components in electrical control systems. Understanding how to correctly wire Siemens contactors is crucial to ensuring an efficient operation. In this informative article, we will provide you with a thorough explanation of Siemens contactor wiring diagrams and how to implement them effectively. Siemens contactors are widely used to establish or interrupt an electrical circuit. These components are frequently used in a variety of electrical applications, such as heating, lighting, and motor control. The Siemens contactor wiring diagrams include instructions on how to connect the various terminals. These diagrams are usually included in the product documentation. To wire the power supplies, make sure to disconnect the power source first.

New sex and the city 2023

Use these tips to learn how to wire a contactor. All timers have a register that contains the current flow value of the time. Home about us privacy policy site map View Cart. Timing circuits are electronic circuits that generate precise time delays or pulses. A timer was essentially a finite state machine that increments and decrements a register once per clock cycle. You are moving the power in and removing the ability to have a "normally off" power setting, but that also removes the shock hazard. MCB is an electromagnetic switch or device. It should make it a lot easier to wire everything together. Technically, this is two relays in one. If for any reason a short circuit occurs in the supply line or load line line to line or line to neutral or in case of overload MCB.

Last Updated: February 8,

Route the wires. About This Article. Skip to Content. You are moving the power in and removing the ability to have a "normally off" power setting, but that also removes the shock hazard. Updated: February 8, When configuring the 0 and 1 poles, polarity doesn't matter. Got a question? For those of you that are curious, I did can a Dremel and cutting wheel and open one up some time ago, so I could take pictures. You Might Also Like. Read Also: 3 phase transformer wiring 3 phase motor contactor diagram Change Over With Electric Motor wiring 3 phase contactor wiring diagram Timer contactor wiring diagram Advertisements. All Categories. De-energize the contactor. Ricardo Mitchell. A loop is a fastener consisting of a ring that protects the inside surface of a small hole.

You are mistaken. I suggest it to discuss. Write to me in PM.