B and q shed base

A firm, level base should be the starting point for any shed or garden building. Without this the structure is likely to be assembled improperly - screw holes will not line up correctly, doors may not fit their doorways and the quality and service life of your shed b and q shed base be greatly gckeylogin.

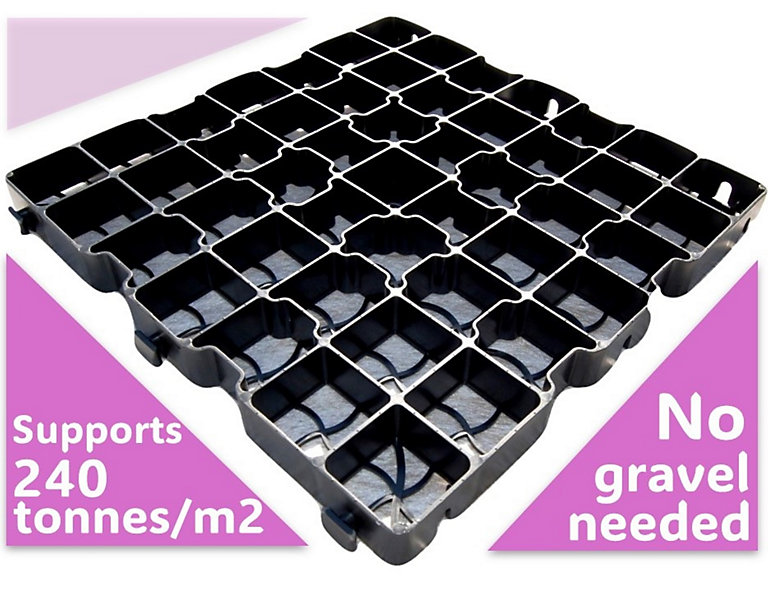

Lay the necessary foundations to ensure that your garden shed is built to last with our easy-to-install shed bases. Ensuring your shed remains sturdy, level, and secured to the ground can prevent the shed from dislodging due to harsh weather conditions and structural damage from gradual movement. A storage shed foundation creates a watertight seal to avoid rot, pests, and water damage with our range of wooden or plastic shed bases in a range of sizes and styles to fit any garden storage structure. From a basic shed base to an elevated shed base grid, find what you're looking for online today. See more Garden buildings. Plastic Interlocking shed base W 49cm x L 49cm , Pack of 4.

B and q shed base

Our garden shed bases and flooring kits provide sturdy, durable, and protective foundations for your sheds and outdoor buildings. From natural stone pavers to plastic shed bases , there are plenty of options to create the look you want for your garden. Shed bases are an excellent way to raise your garden shed a few inches from the ground, protecting against sodden soil and ensuring an even floor. Bases support the weight of your shed and let air circulate beneath, so you can enjoy your garden storage or workspace for many years to come. Choose shed bases in a variety of sizes and materials from Wickes. From wood to recycled plastic, our shed bases add durability to your structure. Discover lightweight shed bases that are easy to carry and fit, so anyone can get the job done quickly. When you install a base for your metal shed , wooden playhouse, or garden office , you guarantee a functional, long-lasting outside building. Browse the Wickes collection for high-quality products you can trust. Track Order. Project list. Filter products Products per page 30 60 90 Wickes Ground Grid Base - x cm. Shire Adjustable Base for 6 x 6ft Sheds.

When the first row is complete, lay slabs along the two adjacent outer edges. Create the wooden pegs by cutting one end of 50mm x 50mm pieces of timber into sharp points using a panel saw, b and q shed base. It arrived 3 days later allowing her to start construction.

Follow along with the video below to see how to install our site as a web app on your home screen. Note: This feature may not be available in some browsers. If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you. Are you a trade or supplier? You can create your listing free at DIYnot Local. How to

A firm, level base should be the starting point for any shed or garden building. Without this the structure is likely to be assembled improperly - screw holes will not line up correctly, doors may not fit their doorways and the quality and service life of your shed could be greatly reduced. There are a number of different options to create the necessary flat and level surface, and we're going to take you through four of them. All are ideal to prevent water collecting around the shed floor and damaging it. These four methods are how to lay:. Both paved and concrete bases can't be laid straight onto soft ground and so require a sub-base. A concrete base also has a further extra step - constructing the frame or edging that supports concrete while it sets, this is known as formwork.

B and q shed base

Lay the necessary foundations to ensure that your garden shed is built to last with our easy-to-install shed bases. Ensuring your shed remains sturdy, level, and secured to the ground can prevent the shed from dislodging due to harsh weather conditions and structural damage from gradual movement. A storage shed foundation creates a watertight seal to avoid rot, pests, and water damage with our range of wooden or plastic shed bases in a range of sizes and styles to fit any garden storage structure.

Empinada cogiendo

After a little research online, they came across our website a found our range of fully recycled plastic shed bases. Step 1 Spread out the timbers into position, roughly where the shed is to be located. If you're using a grid pattern, the first and last slabs on alternate rows will be half slabs. Bases support the weight of your shed and let air circulate beneath, so you can enjoy your garden storage or workspace for many years to come. So do bear in mind that these options can take longer to build than the timber and plastic bases. Cut in the external edges of the paving flush with the slab as you go with a trowel. If the base is located on a hard floor level paving or concrete , only the L-shaped feet are required. JavaScript is disabled. You are using an out of date browser. Shire Adjustable Base for 10 x 7ft Sheds. Step 7 To remove excess concrete and level the surface, go back to the end where you started and slide the tamping board backwards and forwards in a sawing motion across the site. Material Up chevron Plastic.

Are you wondering how to build a shed? In short, yes you can and you can even make it a lot nicer!

Safety first Wash hands thoroughly after handling treated timber and especially before eating. This sub-base is made from an MOT type 1 hardcore consisting of crushed or broken bricks, blocks and stone compacted with an earth rammer or a vibrating plate compactor. When the first row is complete, lay slabs along the two adjacent outer edges. Project list. Step 3 Use a piece of timber and a club hammer or rubber mallet to tap the slab into position. Thanks for your question. So think about that one. Donkmeister 3 Oct Building. Step 2 Use an edger to cut into the lawn for a straight cut, and then use a spade to cut the turf into strips, then roll it up and remove. Assembly instructions will vary depending on the type of timber frame and the shed floor to be fitted, so always follow any specific manufacturer instructions. To remove excess concrete and level the surface, go back to the end where you started and slide the tamping board backwards and forwards in a sawing motion across the site.

It is interesting. You will not prompt to me, where I can find more information on this question?

Willingly I accept. In my opinion, it is an interesting question, I will take part in discussion. Together we can come to a right answer.

Thanks for an explanation. I did not know it.