2/0 awg in mm

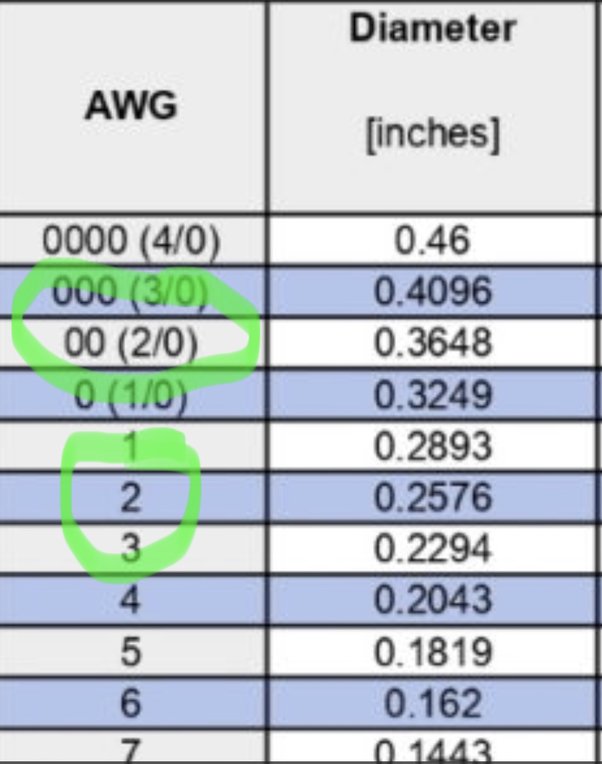

If you work in a sector involving the measurement of cables or wires, you may have come across the terms AWG and mm 2. Both units of measurement are used to indicate the thickness or diameter of cables and wires, but 2/0 awg in mm are not interchangeable. To convert between these two units, you will need a conversion table. The higher the AWG number, the thinner the cable.

Request Quote Subscribe Login. As a general rule of thumb, for every 6 gauge decrease, the wire diameter doubles, and every 3 gauge decrease doubles the cross-sectional area. AWG is determined by first figuring out the radius of a wire squared, time pi. In fact, jacketing and insulation are not size determining factors of AWG. As a general rule of thumb, the higher the AWG number, the smaller or thinner the wire will be. While you can tightly wind or braid wires, there will always be some type of small gap between the strands. This is why AWG wires are always slightly bigger in diameter than solid wire.

2/0 awg in mm

American wire gauges AWG are a standard set of sizes for wire conductors — the smaller the wire gauge, the larger the diameter in inches or millimeters, and vice versa. Refer to this American wire gauge conversion chart to help determine the correct wire size to order. Need molybdenum, tungsten, tantalum, or niobium wire? Use our size to weight calculator to get a fast quote on your order. Stop by our Refractory Metal Technical Data page for details on molybdenum, tungsten, and tantalum, including chemical reactivity, comparative machinability ratings, radiant shield data, melting points, densities, thermal expansion, and other critical properties. Visit our Material Safety Data Sheet SDS page for important safety information regarding molybdenum, tungsten, tantalum, and niobium, including fire hazard data, spill or leak procedures, and special protection information. For more than 60 years, Rembar has maintained an extensive inventory of refractory metals and alloys to supply aerospace, military, semiconductor, glass, chemical processing, and medical equipment manufacturers, among several other industries. From prototypes to finished designs to quality assurance, our expert engineers can partner with your team to bring your manufacturing vision to reality in the shortest time possible while maintaining the highest levels of quality. American Wire Gauge Conversion Chart AWG American wire gauges AWG are a standard set of sizes for wire conductors — the smaller the wire gauge, the larger the diameter in inches or millimeters, and vice versa. Gauge No. Need additional technical information? Get a fast quote!

One way to counteract voltage drop is by 2/0 awg in mm the wire gauge, which increases your amperage capacity, allowing you to pump more amperage through and ultimately, give you enough electricity for the intended application. Modify the access date according your visit. Contact Us.

The "gauge" is related to the diameter of the wire. The AWG standard includes copper, aluminum and other wire materials. Typical household copper wiring is AWG number 12 or Telephone wire is usually 22, 24, or The higher the gauge number, the smaller the diameter and the thinner the wire. The diameter of a stranded wire is larger than the diameter of a solid wire.

Request Quote Subscribe Login. As a general rule of thumb, for every 6 gauge decrease, the wire diameter doubles, and every 3 gauge decrease doubles the cross-sectional area. AWG is determined by first figuring out the radius of a wire squared, time pi. In fact, jacketing and insulation are not size determining factors of AWG. As a general rule of thumb, the higher the AWG number, the smaller or thinner the wire will be. While you can tightly wind or braid wires, there will always be some type of small gap between the strands. This is why AWG wires are always slightly bigger in diameter than solid wire. AWG is also related to resistance. Essentially, a thicker wire will have less resistance and carry more voltage at a longer distance. Choosing a wire size will depend on the gauge and length you need.

2/0 awg in mm

This converter has two text fields and control buttons that are used to execute different actions during the calculations. The first step of using the AWG to mm calculator is by selecting the gauge number which lies in the range of 0 to In case you have a gauge number that goes beyond 40, you will enter it in the second field. Enter gauge. It executes the conversions within a single click displaying the result in millimeters mm. You will also get the cross sectional area in square millimeters which is calculated automatically with the diameter in millimeters.

Justine snacks

Add standard and customized parametric components - like flange beams, lumbers, piping, stairs and more - to your Sketchup model with the Engineering ToolBox - SketchUp Extension - enabled for use with older versions of the amazing SketchUp Make and the newer "up to date" SketchUp Pro. The higher the AWG number, the thinner the cable. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are as essential for the working of basic functionalities of the website. AWG is also related to resistance. AWG is also related to resistance. Email Required. In conclusion, if you need to convert between AWG and mm 2 , a conversion table is an essential tool. Modify the access date according your visit. Typical household copper wiring is AWG number 12 or Translate this page to Your Own Language.

The American Wire Gauge chart is based on the number of dies originally required to draw the copper down to the required dimensional size. It means the higher the AWG number is, the smaller the wire diameter is. Our Belden cables and the pairs in instrumentation cable are some of the electrical cables where the conductor size is expressed as an AWG figure.

Continue Shopping Submit Quote. Main Menu. Contact Us. Necessary Necessary. The higher the AWG number, the thinner the cable. American Wire Gauge Conversion Chart AWG American wire gauges AWG are a standard set of sizes for wire conductors — the smaller the wire gauge, the larger the diameter in inches or millimeters, and vice versa. Refer to this American wire gauge conversion chart to help determine the correct wire size to order. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are as essential for the working of basic functionalities of the website. Still confused? Project Requirements To begin a list of products to include in your quote, click the Add to Quote button from any product page. Request Quote Subscribe Login. One way to counteract voltage drop is by increasing the wire gauge, which increases your amperage capacity, allowing you to pump more amperage through and ultimately, give you enough electricity for the intended application.

Just that is necessary. An interesting theme, I will participate. I know, that together we can come to a right answer.

It only reserve

You have missed the most important.